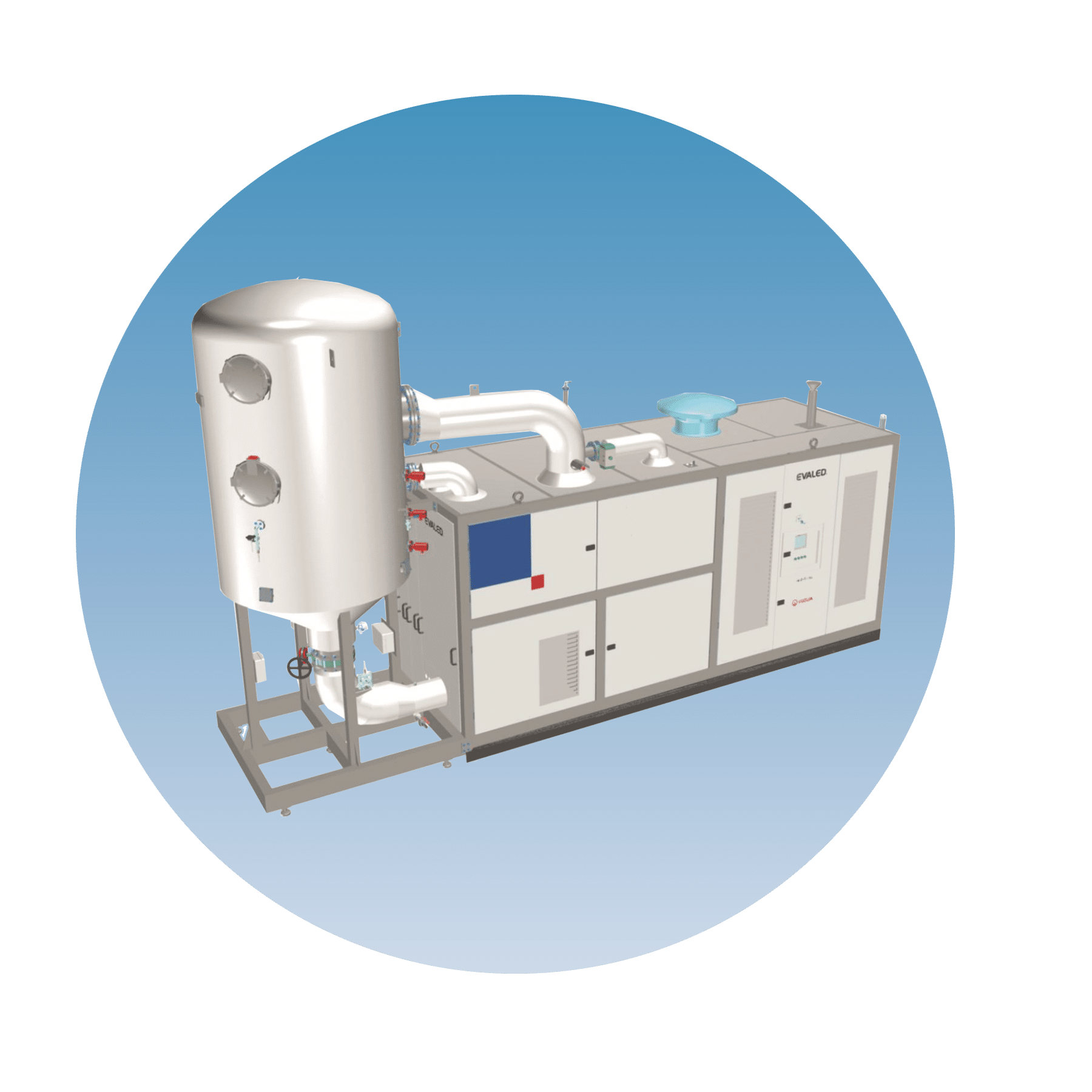

PRAB Evaled Vacuum Evaporation

Proven to Reduce Water Costs Up to 99%

Evaporation and Crystallization-a Clean Solution

For 30 years, EVALED® Evaporators and Crystallizers have provided industrial water and wastewater treatment solutions throughout the world. EVALED heat pumps, hot/cold water evaporators, and mechanical vapor recompression (MVR) units offer clean technology for a wide range of industrial applications.

EVALED Applications

- Exhausted oil emulsions

- Tumbling baths

- Parts rinsing waters

- Ion exchange regeneration

- Reverse osmosis concentrates

- Cooling tower blow-down

- Pretreatment baths

- De-greasing baths

- Phosphate coating baths

- Pickling baths (H2SO4, HCl, HF, HNO3)

- Rinsing baths (cyanide, copper, zinc, nickel, cobalt, cadmium, chromium)

- Mixed stream wastewater

Matching the application and material is critical to reduce corrosion and protect your investment. EVALED technology offers the highest quality products and material selection, with fit-for-purpose materials.

- AA (AISI 316 L)

- FF (Super Duplex)

- HH (Nickel Alloy)

- KT (Teflon® SiC)

Backed by the PRAB Difference

Decrease Washwater & Detergents Costs Up to 75%

No air emissions ever! EVALED evaporator technologies operate as a closed loop system under vacuum. Atmospheric evaporators lose valuable energy through air emissions and may require an air permit or waiver for compliant operation. EVALED evaporators have an efficient design with one inlet and two discharge streams – concentrate and distillate.

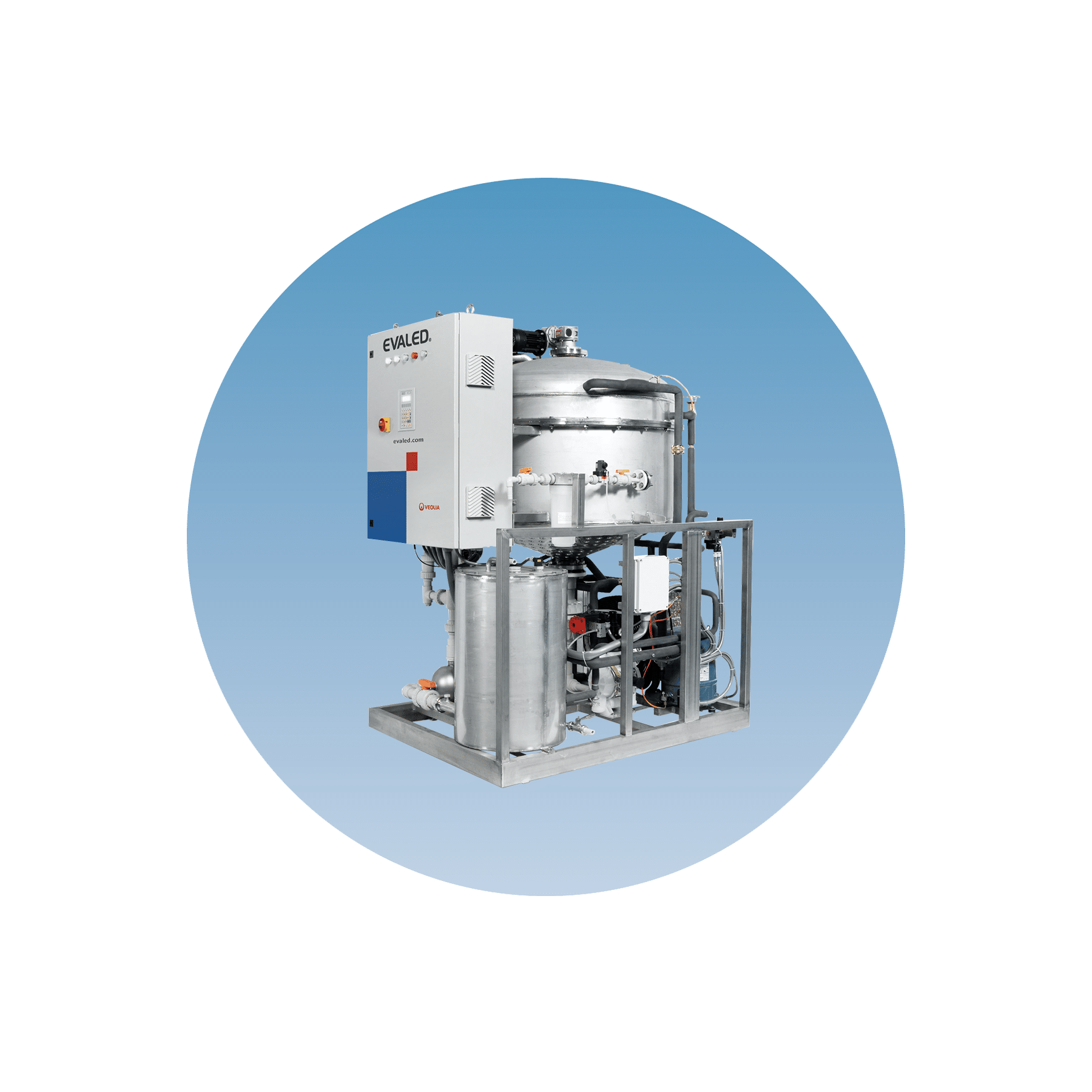

PC- Heat Pump Vacuum Evaporators

PC heat pump evaporators offer flexibility, low electrical energy consumption, and superior reliability.

- Operating pressure of 7-9 kPa (1.0–1.3 PSIA)

- Lowest boiling temperatures: 30-40 °C (86-104 °F)

- Ozone friendly refrigeration gas (R 134)

F Series Evaporators

- Designed to treat low to medium wastewater flow rates and produce maximum distillate quality.

- Forced circulation and low boiling temperatures reduce rates of scaling, corrosion, and fouling.

- Capacities range from 700-24,000 L (185-6,340 gal) of distillate production per day.

R Series Evaporators

- Designed for low flow, highly contaminated or pre-concentrated waste streams.

- Scraped surfaces allow treatment of precipitating waste streams or crystallization of concentrate to achieve Zero Liquid Discharge (ZLD) goals.

Contact us for questions about your specific application

Achieve Zero Liquid Discharge Goals

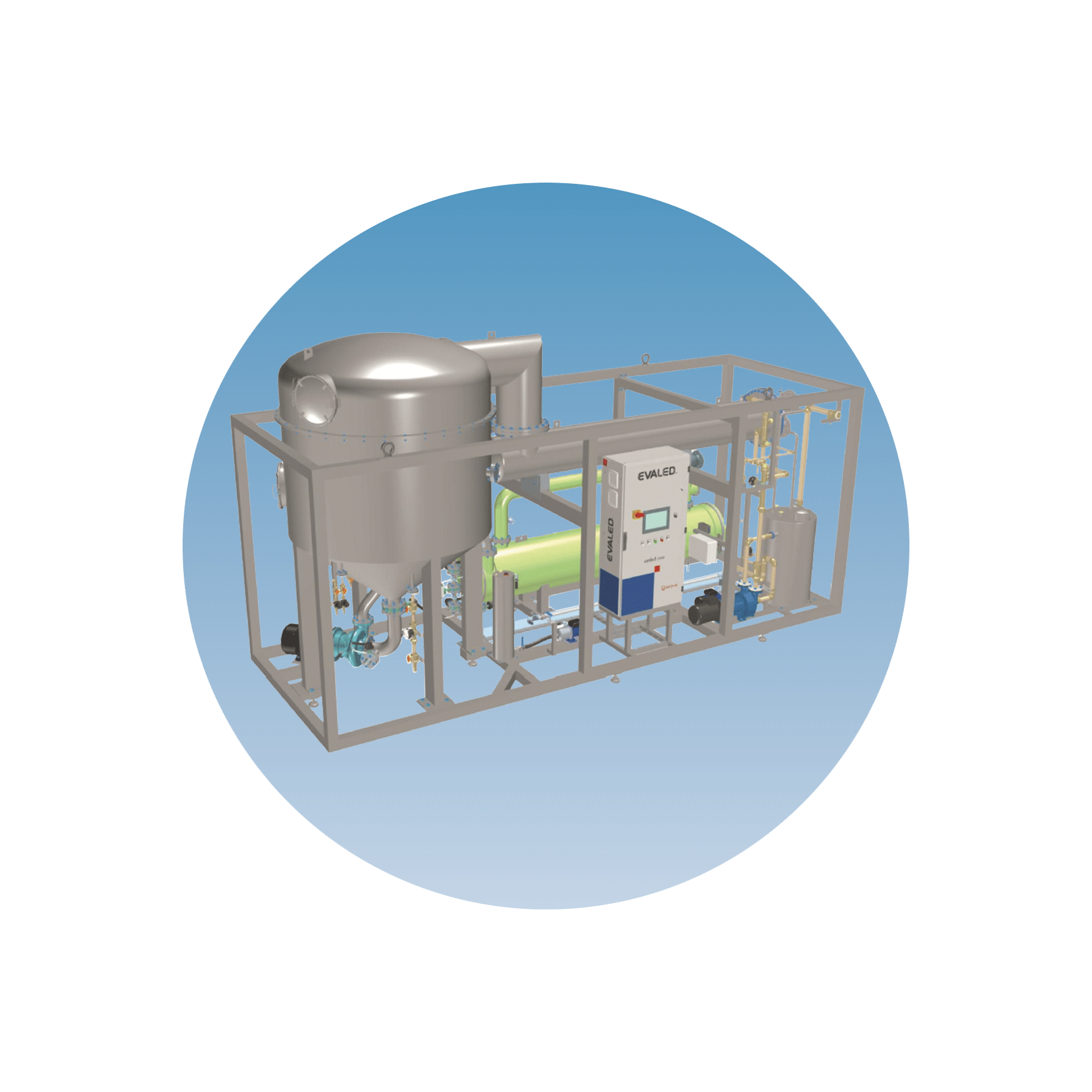

AC- Hot Water/Cold Water Vacuum Evaporators

Reduce operating costs by utilizing excess hot water/steam and cooling water.

- Operating pressure of 4-30 kPa (0.6-4.4 PSIA)

- Lower Boiling Temperatures: 30-70 °C (86-158 °F)

- Single and multiple effect units available

ACF Series Evaporators

- Capacities range from 20,000-60,000 L (5,300-15,800 gal) of distillate production per day.

- Forced circulation reduces scaling, deposits, and fouling.

ACR Series Evaporators

- Scraped surfaces allow treatment of precipitating waste streams or crystallization of concentrate to achieve Zero Liquid Discharge (ZLD) goals.

- Engineered to work in either continuous or batch mode processes.

Backed by a PRAB 100% Performance Guarantee

Eliminate Haul-Away Costs

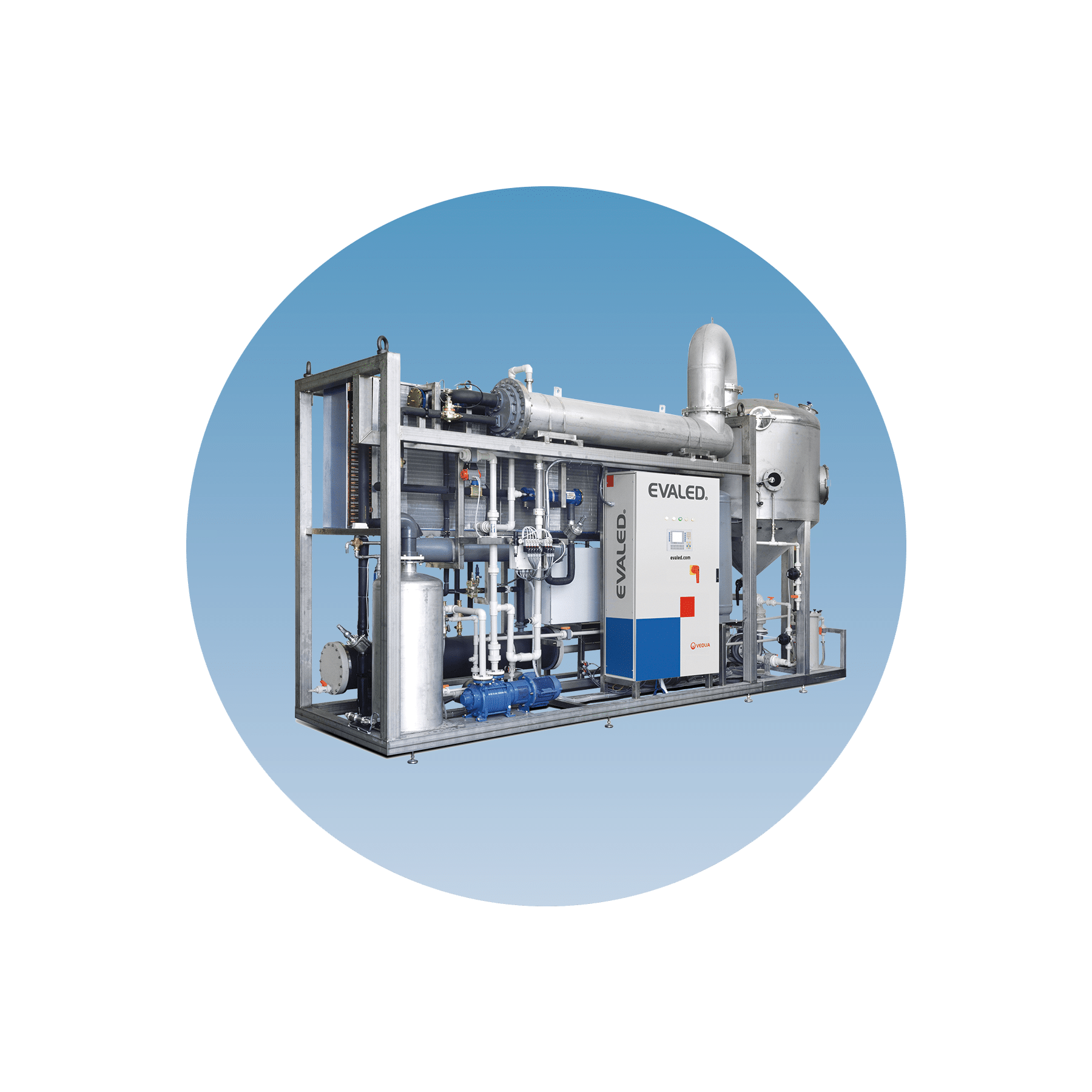

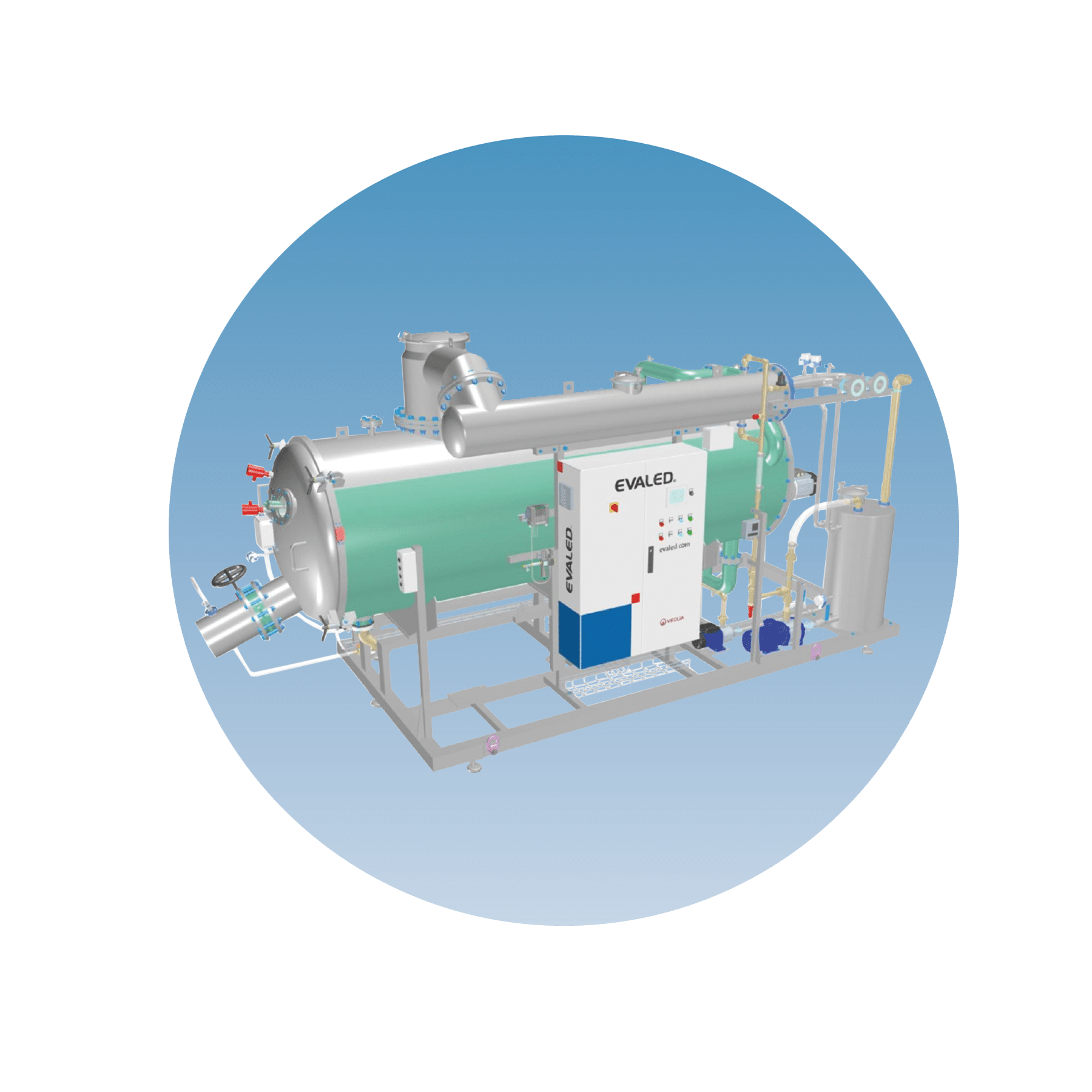

RV- Mechanical Vapor Re-compression

Engineered for the treatment of large wastewater flow rates with low energy consumption.

- Operating pressure of 60-70 kPa (8.7–10.2 PSIA)

- Low Boiling Temperatures: 80-90 °C (176–194 °F)

RVF Series Evaporators

-

- Capacities range from 10,000-120,000 L (2,600-31,700 gal) of distillate production per day.

- Forced circulation reduces scaling, deposits, and fouling.

- Electrical energy consumption: 40 kWh/ton of distillate (0.11 kWh/gal).

MVR Series Evaporators

- Electrical energy consumption: 30 kWh/ton of distillate (0.11 kWh/gal).

- Capacities range from 100,000-200,000 L (26,400-52,800 gal) of distillate production per day.

- Designed for high flow rates and treatment of wastewater with heat sensitive contaminants.

Contact us to request a quote today