Nickel in wastewater

PRAB EVALED® Vacuum Evaporator (model PC F 24FF)

70-90% of distillate is recovered and reused

A well-known manufacturer in the memory storage industry was searching for a solution to their increasing disposal costs and significant storage problems that were occurring as a result of the amount of wastewater coming from their acid pickling rinse baths containing Nickel.

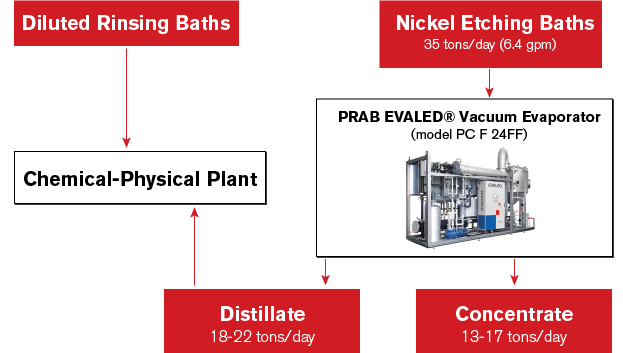

Because no two wastewater streams are exactly alike, in order to find the best solution to meet the plant’s goals and application, a careful review of their process was completed, along with a thorough testing and analysis of the wastewater. It was then determined that a PRAB EVALED® Vacuum Evaporator (model PC F 24FF) would be the best solution and it was added to the plant’s wastewater treatment process.

New Treatment Process Results:

| Parameters | u.m. | Waste In | Distilled Out | Concentrate Out |

|---|---|---|---|---|

| COD | ppm | 50,000-60,000 | 1,000-4,000 | |

| Conductivity | µS/cm | 160,000-220,000 | 400 | |

| TS at 105˚C | % | 16-18 | 35-40 | |

| pH | – | 4.7-5.4 | 4.6 | 5.5 |

| Ammonium | – | 17,000-32,000 | <300 | |

| Nickel | ppm | 5,500-6,500 | <2 | 12,000-15,000 |

After adding the new vacuum evaporator to the process, the plant saw a significant reduction in sludge and disposal costs. Now, 70-90% of distillate is recovered and reused in the production process—which has resulted in a system payback within 8-months of installation.