Chrome Plating Process Achieves Cost Reduction Through Zero Liquid Discharge

CHALLENGE

A global manufacturer of automotive components was faced with rising costs related to waste disposal from a Chrome plating process used in a plant in Poland. The plant manufactures shock absorbers for passenger vehicles. The plating of the shocks adds corrosion resistance, increased surface hardness, and improves cleaning ability and overall appearance.

INDUSTRY

Automotive Manufacturing

PRODUCTS UTILIZED

Evaled® Heat Pump Evaporator

Download PDF

Project Goals:

1) Reduce waste disposal costs

2) Reuse the chromium oxide back in the working bath

3) Provide materials of construction (MOC) suitable to handle aggressive chromic acid without corrosion issues

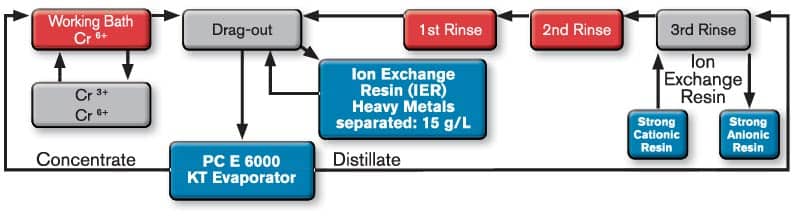

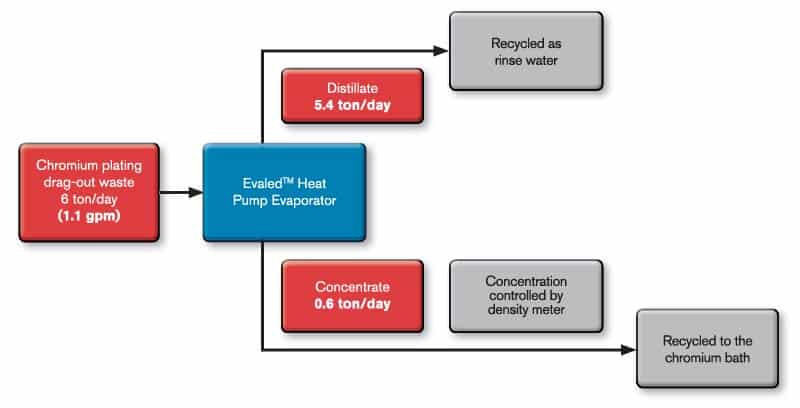

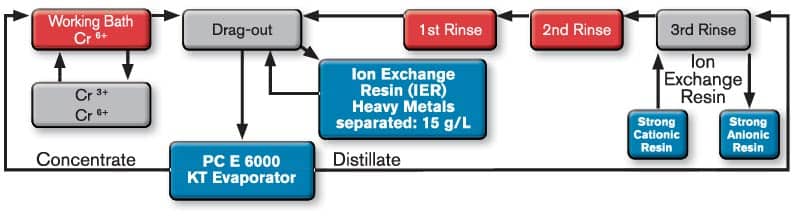

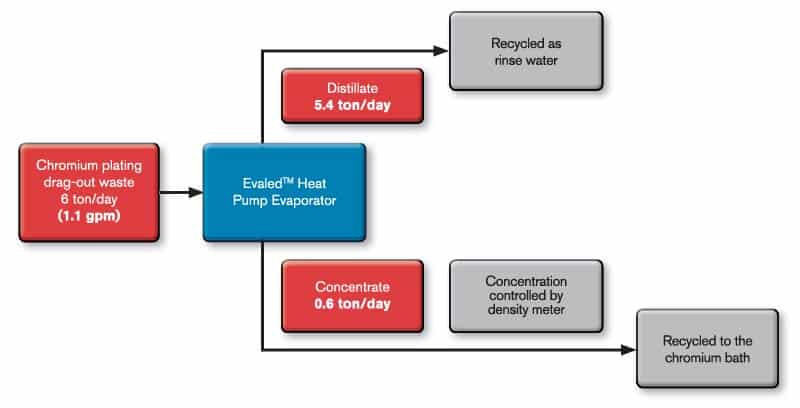

Process Diagram

Plant Analysis

Parameters

Unit

Waste In

Distillate Out

Concentrate Out

Condutivity

μS/cm

<25000

<200

–

Cr6+

g/L

3.5 – 5

<0.02

30

Technology Type

Material

Footprint (ft2)

PC Forced Circulation E 6000 KT

Heat exchanger: Silicon carbide and PVDF Boiling vessel and other wetted parts: Austenitic stainless steel coated with ECTFE

88.26

Results

Distillate Recovered

~ 90%

Concentration Factor

~ 10x

- Complete Zero Liquid Discharge, waste water reduction 100%

- Concentrate recycled to the chromium bath (Bath concentration adjusted by adding either chromic anhydride or demineralized water)

- Galvanic line OPEX reduction