A market leader, specializing in the manufacturing of die-cast aluminum and zinc components for the automotive industry produces a variety of parts that vary in weight up to 40 lbs.

This customer aimed at reducing the wastewater volume coming from the production process, the relative high disposal costs, and to reuse the water within the manufacturing cycle. The wastewater contains mainly oils and glycol.

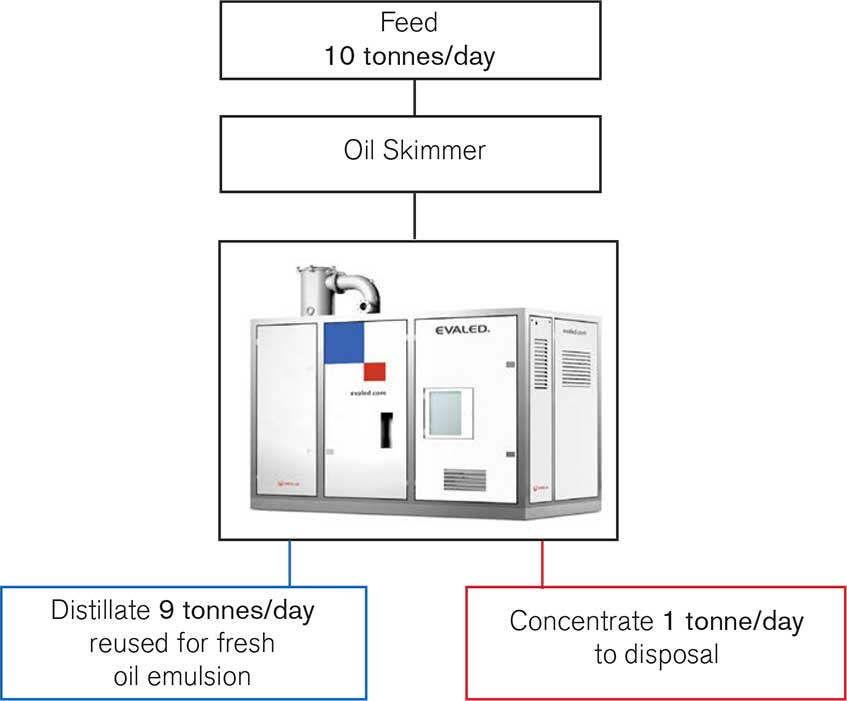

The main component of the equipment supplied is an mechanical vapor re-compression evaporator-EVALED RV F 15-with a distillate production capacity of 15 t/day and a footprint of 26.9 ft2.

EVALED RV F is a range of energy efficient forced circulation evaporators dedicated to oily wastewater treatment allowing for significant waste volume reduction and water recycling.

Highly adaptable, the Mechanical Vapor Recompression (MVR) have proven to be an effective solution for wastewater treatment in a wide range of industrial applications. It has a long track record in the mechanical and surface treatment sectors, where it is used to separate contaminants (as oils, glycols, heavy metals, salts, surfactants, etc.) from the wastewater, thus allowing for significant waste costs reduction and improving the ecological footprint of the production plant. The system includes an oil skimmer, a distillate filter, distillate and concentrate storage tanks and a control system that enables remote management of the entire system.