For over 30 years, Evaled evaporators and crystallizers have provided wastewater treatment solutions throughout the world. Evaled Heat Pumps, Crystallizers, and Mechanical Vapor Recompression (MVR) units offer clean technology for a wide range of industrial applications, including:

Matching the application and material is critical to reduce corrosion and protect your investment. Evaled technology offers the highest quality products and material selection, with fit for purpose materials AISI 316 Stainless Steel, Super Duplex Stainless Steel and Nickel Alloy

EVALED® Vacuum Evaporators are an effective fluid waste management solution for concentrating and removing salts, heavy metals and a variety of hazardous components- reducing wastewater volumes and producing high quality, reusable distillate (ZLD). This industrial evaporation system is fully automated, and modular units are low in energy consumption with a low CO2 footprint. No air emissions, ever!

Benefits of all EVALED® Evaporators include:

EVALED® heat pumps, hot/cold water evaporators, and Mechanical Vapor Recompression (MVR) units offer clean separation technology for a wide range of industrial wastewater treatment applications including:

Hot/cold water evaporators enable the use of low or no cost energy sources – excess hot water or steam that is already available from cogeneration or cooling plants. Using existing waste heat to power the evaporation process reduces operational costs to only the power needed to run the recirculating pumps and/or scraper.

Hot/Cold Water Evaporators feature:

The evaporators are available in two series using different heat transfer technologies:

Hot/Cold Water evaporator with forced circulation and external shell & tube heat exchangers

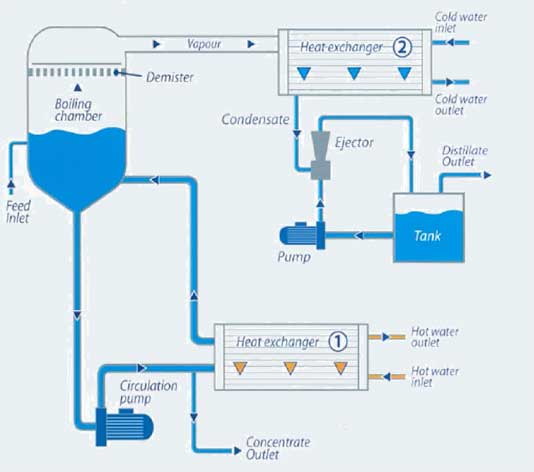

The AC F series evaporator is a hot/cold water evaporator with forced circulation and external shell & tube heat exchangers. The heat necessary to boil the wastewater is delivered by customer supplied hot water; the cooling necessary to condense the vapor is delivered by customer supplied cold water.

Hot/Cold Water evaporator with external shell & tube heat exchanger and scraped heating surfaces

The AC R series evaporator is a hot/cold water evaporator/crystallizer with a scraped boiling chamber and a hot water heating jacket. This series is designed to treat wastewater containing a high concentration of suspended and/or dissolved solids. An Archimedes-screw type scraper prevents any fouling of the heat exchange surfaces. An RW unit often follows a primary evaporator in series to provide further concentration or crystallization of the concentrate.

With the addition of an optional intermediate heat exchanger, RW evaporators can also utilize excess steam as a heat source. Optional heat pump conversion kit enables operation when excess hot water or steam is not available.

The heat pump evaporator is the core of the Evaled line and offers flexibility, low electrical energy consumption, and superior reliability. Evaporation occurs under high vacuum conditions, consuming 25x less energy and providing better control of foaming than units operating closer to atmospheric pressure. The reduced carry-over of contaminants produces a high quality distillate stream for low to medium flow wastewater treatment applications.

Heat Pump Evaporators feature:

Heat pump evaporators are available in two series using different heat transfer technologies:

Heat pump evaporator with forced circulation and external shell & tube heat exchanger.

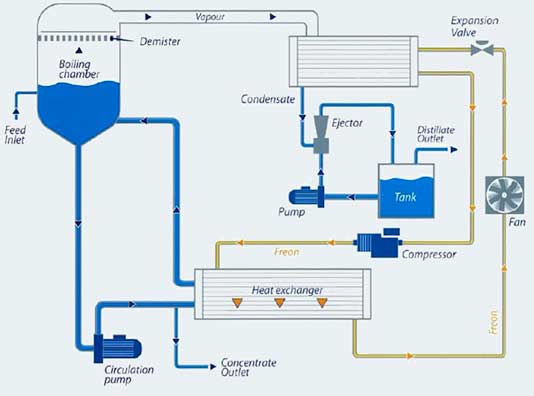

PC F series heat pump evaporators are designed to produce maximum distillate quality with minimal capital and operating costs. PC F series evaporators operate under high vacuum conditions (1.0 – 1.3 PSIA), reducing the boiling temperature of the wastewater to 86 – 104°F. This reduced operating temperature significantly inhibits the rates of scaling and corrosion based chemical reactions and decreases the maintenance required as a result. Each unit is skid-mounted for simple installation and controlled by PLC, allowing continuous 24/7 operation.

Heat pump evaporator with scraped heating surfaces

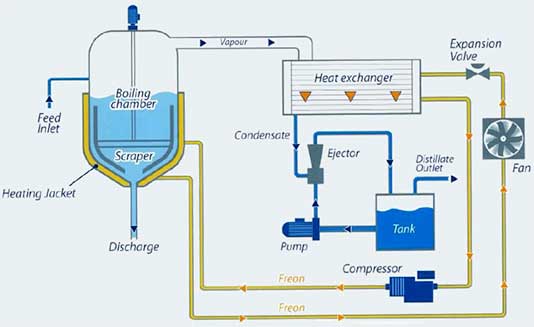

The PC R series evaporator is a heat pump evaporator/crystallizer with a scraped boiling chamber and a heating jacket. This series is designed to treat wastewater containing a high concentration of suspended and/or dissolved solids. The continuously stirred scraper prevents any fouling of the heat exchange surfaces. An R unit often follows a primary evaporator in series to provide further concentration or crystallization of the concentrate.

As a result of low operational costs due to minimal electrical energy consumption, mechanical vapor recompression (MVR) technology evaporators allow the treatment of high flow rates of wastewater with a return on investment that can often be measured in months. The MVR units contain no refrigeration circuit; they utilize the heat of compression added by a rotary lobe type compressor to superheat the wastewater vapor, then transfer that heat through an exchanger to boil the incoming wastewater.

The MVR units are available in three series, using two different heat transfer technologies:

TC series and the new generation RV F Series: Mechanical vapor recompression evaporators with forced circulation and external shell & tube heat exchanger

The TC series evaporator is based on the mechanical vapor recompression technology, and uses forced circulation through an external shell & tube heat exchanger to evaporate the wastewater in the boiler. The forced circulation of the wastewater reduces scaling, deposits, and fouling on the heat exchange surfaces.

The RV F series evaporator is an evolution of the TC series and improves upon the existing technology to increase distillate quality, reduce energy consumption, reduce footprint, and add updated controls and automated cleaning.

Mechanical Vapor Recompression evaporators with forced circulation and falling film heat exchanger

The R V series evaporator is based on the mechanical vapor recompression technology, but uses a forced circulation, falling film heat transfer device to evaporate the wastewater in the boiler.

Due to the low temperature differences between the heat exchanger and boiling wastewater, the falling film technology allows for the successful treatment of wastewaters containing highly corrosive (acidic or alkaline) contaminants or heat-sensitive products to be recycled.

Below are a few example system flow diagrams featuring an EVALED® Vacuum Evaporator. Each solution is customized to your unique application according to your goals and requirements.

Full Spectrum Industrial Wastewater Recycling and Reuse. Cost Reduction, Waste Minimization & Environmental Compliance.

Agenda

Matching the application and material is critical to reduce corrosion and protect your investment. EVALED® filtration technology offers the highest quality products and materials selection, with fit-for-purpose components:

Product Brochures

Product Brochure: EVALED Vacuum Evaporation

Product Brochure: EVALED Evaporation Technology

Application Review

Application Review: Candy Manufacturer Reduces Wastewater Disposal Costs and Recovers Concentrate for Reuse with Vacuum Evaporation

Application Review: Pharmaceutical Research Laboratory Reduces Wastewater Volume and Disposal Costs with Vacuum Evaporation

Application Review: Chemical Manufacturer Significantly Reduces CO2 Emissions and Wastewater Disposal Volumes with Vacuum Evaporation

Application Review: Battery Recycler Achieves Zero Liquid Discharge (ZLD) and Recovers Over 80% of Concentrate for Resale

Application Review: Microelectronics Manufacturer Reduces Rinse Line Water Disposal Costs and Sludge with Vacuum Evaporation

Application Review: Digital Memory Storage Production Site Solves Acid Pickling Bath’s Wastewater Issues with Vacuum Evaporation

Application Review: Concrete Additives Facility Reduces Wastewater Disposal Costs Through Vacuum Evaporation and Distillation

Application Review: Automotive Components Manufacturer Reduces Wastewater Volumes from Die Casting Process

Application Review: Automotive Manufacturer Drives Cost Reduction and Increases Profitability Through Wastewater Treatment

Application Review: Chrome Plating Process Achieves Cost Reduction Through Zero Liquid Discharge

Application Review: Parts-Cleaning Oily Wastewater Disposal Costs Reduced by Over 90% with Vacuum Distillation

Technical Brief

Technical Brief: Evaporation Technology

White Paper

White Paper: Green Engineering

White Paper: Making Wastewater Compliance Part of A Profit Strategy

White Paper: PRAB Evaporation Technology

White Paper: Prioritizing Plant Housekeeping In A Metalworking Operation

White Paper: Six Feasibility Studies

White Paper: Taking Control of Wastewater Treatment

Other Downloadable Content

PRAB Fluid Filtration Solutions Product Selection Chart Brochure

PRAB Fluid Filtration Systems and Wastewater Treatment Brochure

PRAB Filtration Spectrum Brochure

PRAB Industrial Water & Wastewater Treatment Systems Brochure

PRAB Industrial Water & Wastewater Treatment Technologies Brochure

PRAB Builds Equipment for the Toughest Jobs in Manufacturing and Metalworking

Wastewater treatment has become an increasingly critical part of plant operations over the past decade, and manufacturing companies in all industrial sectors are prioritizing the reduction of water consumption. Compliance with ever-tightening federal regulations for wastewater treatment, handling, and disposal requires finishing-industry executives to focus on the issue. Additional motivating factors for recycling wastewater include strengthening a company’s public image, […]

Certified by third parties on the performance of EVALED® Evaporators EVALED® A brief compendium of EVALED® laboratory analysis competences Mechanical & Surface Treatments Food & Beverage Oil & Gas Feasibility Studies Chemical Analyses EVALED® Mechanical And Surface Processes Automotive, Aviation, Furniture, Appliances Mechanical and surface processes that involve the automotive, […]

Green Engineering How to Design More Profit into the Metalworking Operation By Ron Chapman, Systems Sales Manager & Teresa Phillips, Senior Marketing Specialist, PRAB Introduction The green movement is not a new concept. In fact, the basic principles were well-known throughout Europe in the medieval era. However, it was the Industrial Revolution in Europe that […]