Protect your scrap removal and processing system from metal solids.

The tramp metal separator is primarily used with a PRAB Chip Processing system for removing bar-ends, broken tooling and other solids from the chip flow. This protects the scrap metal equipment from damage- reducing downtime and costly repairs.

PRAB offers a complete line of tramp metal separators and scrap removal systems to remove bar-ends, broken tooling and other solids from chip flow protecting scrap metal equipment from damage. This reduces downtime and saves money on costly repairs.

PRAB’s full-line of tramp metal separators include five unique models that are engineered to perform scrap collection at different levels to efficiently handle the variety of metal chips and turnings produced by today’s high-speed metalworking industry. Models include:

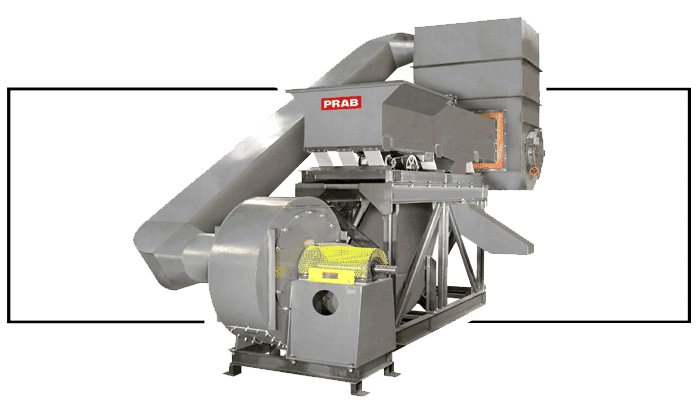

Model O

The Model O is a scrap collection unit that positively separates all types of solids from material flow in preparation for scrap metal recycling. It is a heavy-duty, oscillating, conveyor-fed air classifier designed for large chip processing systems. Typical throughput of metal chips is 200 ft3/hr (5.6 m3/hr). This scrap metal equipment includes a 20 hp blower and plenum system designed to recirculate airflow, reducing misting issues.

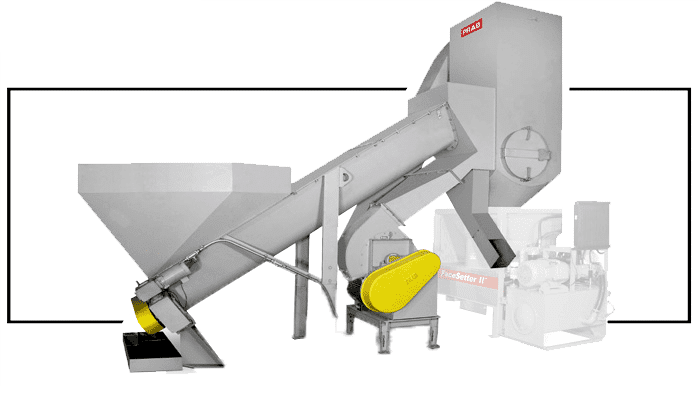

Model V

The Model V contains a vibratory feeder/air classifier that separates solids from wet chips and turnings at a rate of 100 ft3/hr (2.8 m3/hr) in preparation for scrap metal recycling. This scrap metal equipment includes a return air system that recirculates airflow, reducing misting issues.

Model G

The Model G is a scrap collection unit containing a gravity-fed, free-standing air classifier that can process metal scrap at rates up to 80 ft3/hr (2.2 m3/hr). This scrap metal equipment positively separates tramp metal from material flow for scrap collection in preparation for scrap metal recycling. The unit includes a 20 hp blower and plenum system designed to recirculate air flow, reducing misting issues.

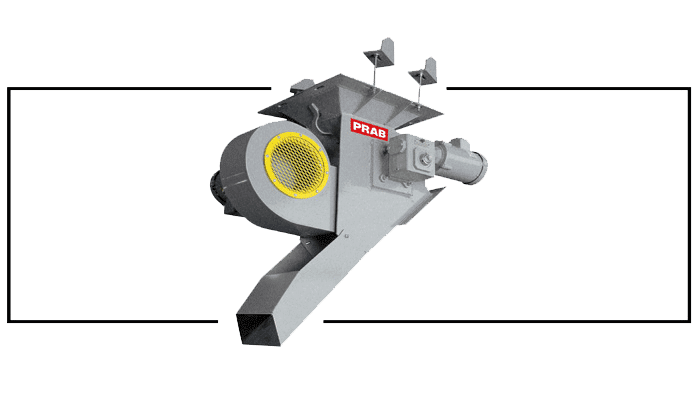

Model R Separator

The Model R Separator is specifically designed to feed PRAB Diagonal-Shaft Wringers. This scrap collection unit incorporates a blower and rotary air lock mounting to the wringer infeed conveyor. Two adjustable plenums control air flow into the wringer infeed. The unit is capable of being “fine-tuned” to divert very small solids from the chip flow. The unit can process metal scrap continuously at rates up to 60 ft3/hr (1.6 m3/hr) in preparation for scrap metal recycling.

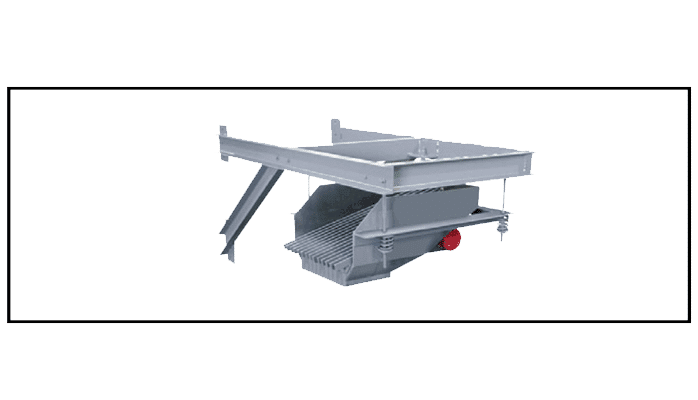

Model S Separator/Screener

Generally used for cast-iron applications, the Model S Separator/Screener is a scrap collection unit with a vibrating bar screener deck. It can be provided as a stand-alone unit or can also be attached to the inlet of a wringer or briquetter to separate flowable chips from solids and reject castings for scrap collection in preparation for scrap metal recycling.

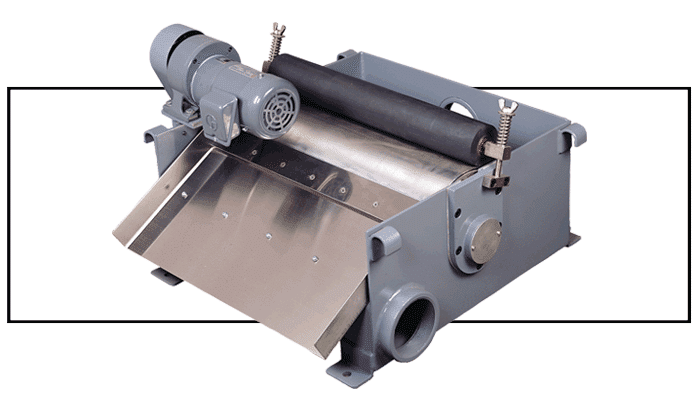

Magnetic Separator

Magnetic tramp metal separators employ high-intensity ferrite or rare earth magnets within a fully energized rotating drum to continuously remove ferrous particles from the flow of liquid. These systems are often used as a pre-filter to limit contaminants reaching subsequent filtration equipment. Typical applications include centerless and heavy stock removal grinding machines, honing, and gear cutting machinery.

Product Brochures

Product Brochure: Tramp Metal Separator

Product Brochure: E-Series Chip System

Case Studies

Case Study: C&A Tool Increases Profitability, Maintains Clean Facility With Chip Processing System

Case Study: Machining Company Achieves Considerable Cost, Space and Labor Savings with a PRAB Crusher/Wringer System

White Paper

White Paper: Green Engineering

White Paper: Making Wastewater Compliance Part Of A Profit Strategy

Other Downloadable Content

PRAB Chip Processing Systems All Product Brochure

PRAB Builds Equipment for the Toughest Jobs in Manufacturing and Metalworking

Download printable PDF Anthony Screw Products Ltd. is a precision machining company located in Burlington, Ontario, Canada. The company utilizes automatic multi-spindle machines, CNC lathes and mills, and rotary transfer machines to produce a wide range of custom parts including mining, tank and hydraulic fittings, washers, nuts, bolts, pulley hubs, and speaker parts. The privately owned, family-run business […]

Automated Systems and Software Platforms Exist that Can Ease an Operation’s Transition to the Industrial Internet of Things Introduction Smart technology has become a common, if not essential, part of our daily lives. Most people are familiar with smart technology—which is an acronym for Self-Monitoring, Analysis and Reporting Technology—in the […]

The Institute of Scrap Recycling Industries is hosting their annual convention and exposition in historic New Orleans, Louisiana on April 22nd 2017 – April 27th 2017. Scrap recyclers from all over the globe will be attending to showcase their equipment and solutions to scrap recycling challenges. PRAB is a worldwide leader in the design and manufacturing of equipment and systems […]