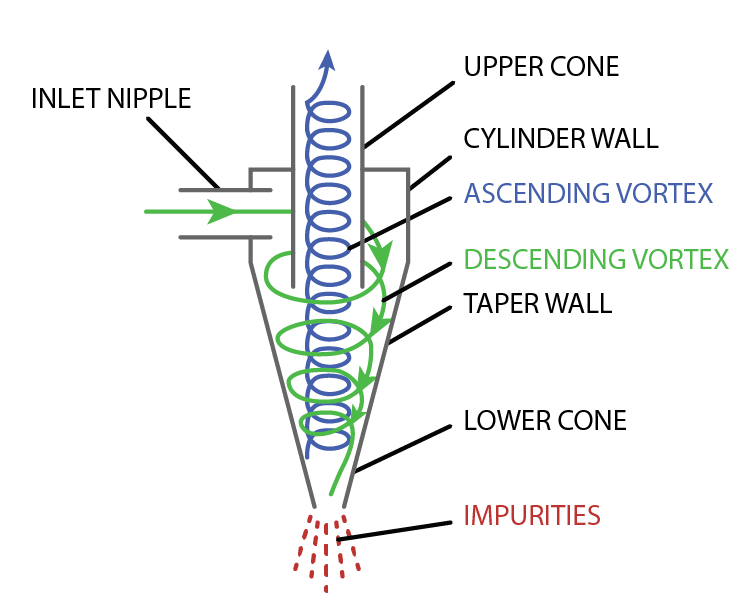

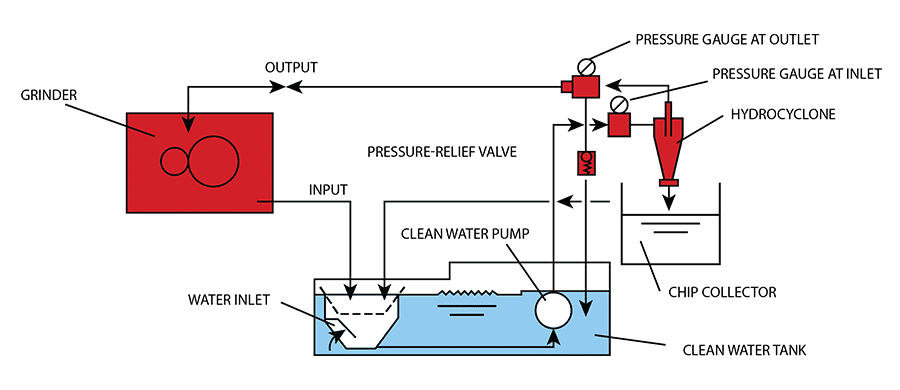

Replacing filter media is time-consuming and expensive. The Hydrocyclone creates ascending and descending vortexes in a cylindrical feed that separates contaminants from coolant without the use of filter media. This design results in consistent, long-term filtration.

| Model | Number of Hydrocyclones | Contaminated Water Flow Rate (GPM) | Clean Water Supply Flow Rate (GPM) | Pressure at Outlet (PSI) | Max. Pressure (PSI) | Feed Pump (HP) | Feed Pump Motor |

|---|---|---|---|---|---|---|---|

| HC-F1 | 1 | 10.5 (40 L/min) |

8 (30 L/min) |

2.8 (0.2kg/cm2) |

7.1 (0.5kg/cm2) |

1 hp (0.75kw) |

50/60HZ 200/220V |

| HC-B1 | 1 | 18 (70 L/min) |

14.5 (55 L/min) |

2.8 (0.2kg/cm2) |

7.1 (0.5kg/cm2) |

2 hp (1.5 kw) |

50/60HZ 200/220V |

| HC-B2 | 2 | 37 (140 L/min) |

29 (110 L/min) |

2.8 (0.2kg/cm2) |

7.1 (0.5kg/cm2) |

2 hp (1.5 kw) |

50/60HZ 200/220V |

| HC-B3 | 3 | 55 (210 L/min) |

43.5 (165 L/min) |

2.8 (0.2kg/cm2) |

7.1 (0.5kg/cm2) |

3 hp (2.2 kw) |

50/60HZ 200/220V |

| HC-B4 | 4 | 74 (280 L/min) |

58 (220 L/min) |

2.8 (0.2kg/cm2) |

7.1 (0.5kg/cm2) |

3 hp (2.2 kw) |

50/60HZ 200/220V |

Download Address the Most Common Issues to Maximize Growth By Teresa Phillips, Senior Marketing Specialist, PRAB Introduction There are numerous areas in metalworking operations that can affect operational profitability, but eight top problem areas are common to many manufacturers. This whitepaper touches on each of the 8 problem areas, explains how they impact profitability, and what can […]

Automated Systems and Software Platforms Exist that Can Ease an Operation’s Transition to the Industrial Internet of Things Introduction Smart technology has become a common, if not essential, part of our daily lives. Most people are familiar with smart technology—which is an acronym for Self-Monitoring, Analysis and Reporting Technology—in the […]

After World War II, as the United States quickly transformed from an agricultural society to an industrial one and the start of the modern-day environmental movement had begun. In the first 25 years of this movement, the US spent more than $1 trillion to address environmental threats caused by commercial activities. Since that time, being environmentally responsible, has been […]