Metalworking’s most versatile belt conveyors for transporting a broad range of materials.

More versatile than other types of conveyors. PRAB steel belt conveyors can be used to handle any type of wet or dry metal scrap- from bushy material and die scrap, to chips and turnings.

This heavy-duty scrap conveyor can process wet or dry metal material in any volume and is available in a wide variety of paths.

Image Right: Auto lube systems are designed to automatically supply a small quantity of clean grease or oil to bearings on a regular basis-improving bearing performance and eliminating maintenance required for manual greasing.

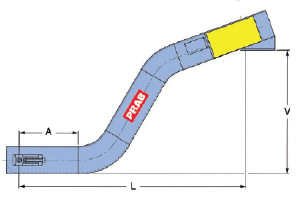

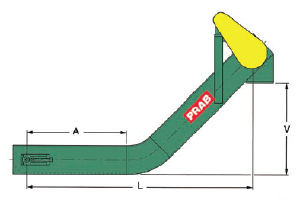

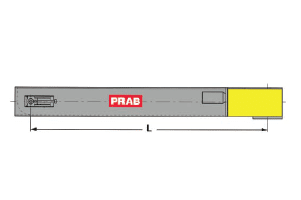

PRAB Steel Belt Conveyors are available in 2.5″ to 9″ pitch and are designed to convey a wide range of metal scrap ranging in weight and bulk density. It’s capable of combining horizontal and elevating movements. Heavy-duty side frames, track and wear bars keep the belt on track shift after shift.

Belt options available to meet differing applications include:

Configurations available include:

PRAB Beaded Pan Steel Belt Conveyor – Well Suited for Severe Environments

PRAB’s Beaded Pan Steel Belt Conveyor is well suited for severe environments and application

PRAB Copper Chips – Steel Belt Conveyor

PRAB’s steel belt conveyor transports copper chips to downstream processing equipment.

PRAB Steel Chips – Steel Belt Conveyor

PRAB’s steel belt conveyor transports steel chips to downstream processing equipment.

PRAB 2.5” Pitch Steel Belt Conveyor Unit

PRAB designs and manufactures a variety of steel belt conveyors, including this 2.5” Pitch unit featuring impact plates for extended service life. Scrap material is collected in the lower horizontal of the conveyor and is then elevated and discharged at a customer specified height. Optional chain oilers provide lubrication of the chain and rollers. Integrated control panels are available for a fully automated solution.

Product Brochures

Product Brochure: Steel Belt Conveyor

Product Brochure: Beaded Pan Conveyor

Application Review

Application Review: A Die Cast Company Improves Melting Process and Cuts Operating Expenses

Application Review: Automotive Powertrain Manufacturer Sees Results BEFORE Installation of PRAB Wringer and Conveyor Through PRAB’s ‘Prove It Before You Use It’ Approach

Application Review: Full-Service Recycler Increases Profits with Orbital Load-Out System

Application Review: Mobile Conveyor Helps a High-Volume Stamping Operation Improve Production and Increase Safety

Case Studies

Case Study: Aerospace Components Manufacturer Turns Its Waste Stream into a Revenue Stream

Case Study: Cashing in Your Chips

Case Study: C&A Tool Increases Profitability, Maintains Clean Facility With Chip Processing System

Case Study: Martin-Baker Turns Scrap Metal and Fluid into Revenue Stream

Case Study: Metal Stamping Company Implements Successful Expansion Project in Partnership with PRAB Conveyors

Case Study: Metalworking Company Finds Increased Asset Utilization by Focusing on Scrap Management

Technical Brief

Technical Brief: Critical Design Elements for Maximizing the Life of Under Press Steel Belt Conveyors

White Paper

White Paper: Avoiding Accidents, Injuries & Illnesses In Metalworking Operations

White Paper: Reallocating Labor in the Metalworking Industry

Other Downloadable Content

Conveyor Solutions

Die Cast Scrap Conveyor Systems

Stamping Scrap Conveyors & Systems

PRAB Builds Equipment for the Toughest Jobs in Manufacturing and Metalworking

Conveyor Performance White Paper

CHALLENGE A die cast company in the Midwest contracts with automotive and other industrial OEM companies to design and manufacture die cast parts from Aluminum, Zinc, and Plastic. The die caster recognized the need to improve the efficiency of their Aluminum remelt processes. The Die Cast industry as a whole has seen shrinking profit […]

“Keeping up with high Q rates” sounds like the title of a reality TV show. It’s definitely an important aspect of any industrial manufacturing operation that puts a priority on optimizing output. If the goal is to machine as many parts as possible in the shortest amount of time to maximize profitability, a high material removal rate (Q) is critical […]

Metalworking operations aren’t struggling to find work these days, thanks to a strong economy and a healthy construction market. Unfortunately, the dwindling number of highly skilled workers with deep industry knowledge poses a more serious problem that must be dealt with to ensure that productivity keeps pace with demand. According to industrial supply company Grainger, 59% of metalworking firms […]