Extend Oil Life

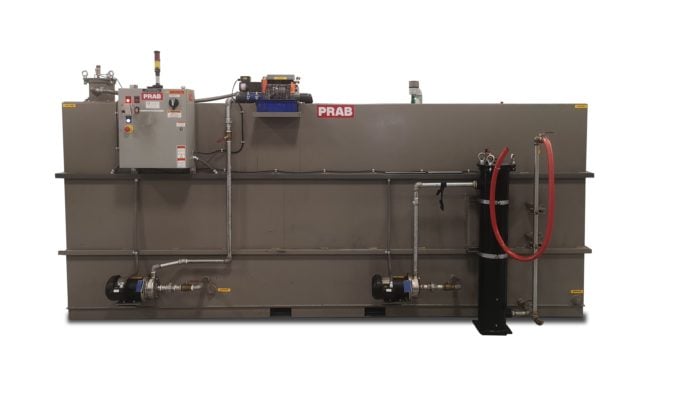

PRAB Oil Recycling System

Centralized, economical, and safe solution for maintaining oil-based coolants

The PRAB Oil Recycling System (ORS) is a centralized, cost-efficient option for maintaining oil-based coolants. The ORS removes the suspended particles and moisture that shorten the useful life of oil-based coolants, reducing new oil purchases by up to 75%. The system provides everything one needs to implement a state-of-the-art fluid management program. Each system is designed for easy installation, quick start-up, and simple, efficient operation.

Standard Features & Benefits

- Machine downtime is reduced by 50% on average.

- Tool life is extended by up to 25%.

- Disposal costs can be minimized by as much as 90%.

- Surface finish is improved by an average of 25%.

- The ORS decreases employee health issues caused by contaminated coolant.

Increase Your Waste Value

PRAB E-Series Metal Chip Processing System

Compact, turn-key system for reclaiming valuable cutting fluid and increasing scrap value

The PRAB E-Series Chip System is a dependable, fully automated system for reclaiming valuable cutting fluid from wet metal chips and turnings. This compact unit was designed for small-to-medium material volumes and can process Aluminum, Brass, Cast Iron, Steel, or Stainless Steel. The system will provide a fast return on investment and is delivered ready to go.

Standard Features & Benefits

- The E-Series is a self-contained and forklift-portable structure.

- Scrap value can be increased up to 25% and up to 99% of cutting fluids can be reclaimed.

- The infeed hopper with screw conveyor moves chips and loose turnings and meter feeds the scrap into an optional turnings shredder or wringer.

- The diagonal shaft wringer (gravity discharge) efficiently removes moisture from chips with over 600 G’s of centrifugal force and produces up to 98% dry chips.

- Exclusive reversing feature extends service life.

- Discharge conveyor transfers processed chips to container.

- The E-Series features a 50-gallon fluid recovery tank.

- An electrical control panel with HMI panel controls all system functions.

Recycle Fluid for Reuse

PRAB Guardian Coolant Recycling System

Designed for easy installation, quick start-up, and simple, efficient operation

PRAB’s Guardian Coolant Recycling System is a centralized, economical solution to the high costs associated with maintaining water-based coolants and washwater in the metalworking industry. The Guardian system recycles used coolants, reduces waste fluids, and eliminates concerns about wastewater haul-away liabilities. Everything you need for centralized coolant recycling is included with the Guardian. Each turn-key system is designed for easy installation, quick start-up, and simple, efficient operation. PRAB backs every Guardian system with a 100% performance guarantee.

Standard Features & Benefits

- Guardian Coolant Recycling systems reduce fluid purchase costs by up to 75% and hazardous waste disposal costs by up to 90%.

- The typical system payback is 6-9 months.

- Easy operation minimizes operator involvement and training.

Cost-Effective Solutions for Fluid Filtration

PRAB Paper Bed Filters

Low-profile, cost effective, solid/liquid separation

PRAB offers a complete line of paper bed filters that provide long-term solutions for solids filtration, with or without magnetic separation, and is perfect for grinding applications. Filtered fluid can be reused or recycled, lowering your operational costs.

Standard Features & Benefits

- Paper bed filters can be used for both ferrous and non-ferrous metals.

- Disposable paper filter media is available in a variety of grades to meet your specific requirements.

- Filter surface is automatically indexed only when needed.

- Filters include automatic self-cleaning and self-monitoring system.

- Applications are oil- and water-soluble.

- Paper bed filters prolong coolant and tool life, improve surface finish of component part, and are perfect for grinding applications.

- A variety of sizes are available ranging from 5-130 gpm.

- Models are available for standard paper bed, magnetic paper bed, and drum-type paper bed filters.