One of the largest expense in manufacturing—especially with the heightened cost of metal today—is probably materials which can drastically affect business profitability. So, in times of inflationary uncertainty, how do you offset the rising cost of material without reducing the quality of your final product while still meeting your customers’ expectations?

Metalworking operations across industries can look at the following possible options to reduce material costs and determine which ones would most effectively meet profit goals.

Where possible, research alternative materials that can be used in the metalworking process to substitute those that are climbing in price. When doing the research make sure to address all factors that could affect quality and customer expectations. For example, replacing higher-cost stainless steel with a carbon steel may save money, but it decreases the corrosion protection of the product which is probably an important benefit to the customer.

Also, keep in mind that by using an alternative material you may need to change the products manufacturing process which could increase other costs. For instance, if the substitute’s material cost is less but the final product will take more labor because of the new manufacturing process there would be no cost benefit for an alternative material.

Find out what customers are really looking for in a product when they buy. What is most important to them, quality, price, or other reasons. Once the most important buying motives have been identified, carefully select features that are not as important to the customer that can decrease costs by eliminating them.

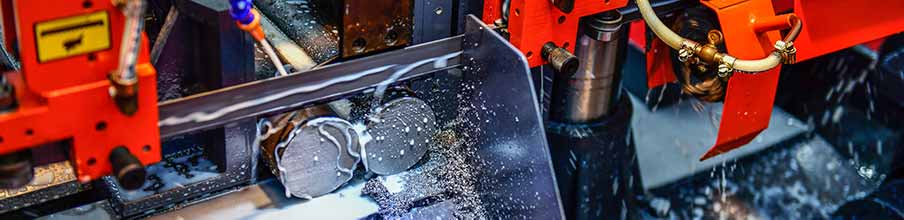

An increasing number of manufacturers are updating their operations with automated control systems to decrease inefficiencies and lower costs. Here are just two examples of how automation can help.

Remotely monitoring equipment provides real-time data allowing for proactive actions when maintaining equipment and production schedules. This programming techniques can reduce labor costs by providing maintenance reminders or alerts for machines that are performing in a way that may indicate there are or will soon be problems with equipment. This is a proactive approach which decreases labor through predictive maintenance initiatives.

Automated machine monitoring helps reduce energy waste/costs. Management teams can monitor machine energy spikes, peak hours, weekend use, wasted hours, and more.

Hiring a metal fabricating contract manufacturer is a great way to cut costs, especially if there are disruptions in your supply chain. Outsourcing also shortens lead times without hiring additional resources.

Because ordering higher volumes often reduces the total price, consider contacting another company that uses your similar supplies and combine orders. Most suppliers treat logistics separately from sales so shipping to different locations should not be an issue.

For more information regarding PRAB, please visit prab.com or contact us.