Electroplating, electroless nickel plating, metal-forming operations, battery recycling and other such operations all generate wastewater containing soluble heavy metal ions. Ultrafiltration and precipitation are the most effective methods for removing these metal ions. Both help manufacturers avoid the costly consequences of non-treatment, that can include corrosion to systems, toxic pollutants passed into surface waters, sludge disposal, and more.

Finding the Method that Works Best

Finding the best method for treatment will depend on a variety of application specific criteria, because the chemical form and concentration of these metals can vary widely. It is also guided by the specific industry the processing site serves, and the type of operation.

In the plating industry, the use of alloy technologies like zinc/nickel and other coatings, has become commonplace to maximize the high corrosion resistance of the metal. Precipitation and the use of polymers in a lamella clarifier, followed by a filter press to dewater the sludge, are among the methods that can effectively treat zinc and chrome wastewater.

With highly complexed alkaline zinc/nickel, which doesn’t want to precipitate, the chelated metals tend to stay in solution, and the high metal concentrations erase the option of discharging to the local publicly owned treatment works (POTW).

Tubular Ultrafiltration

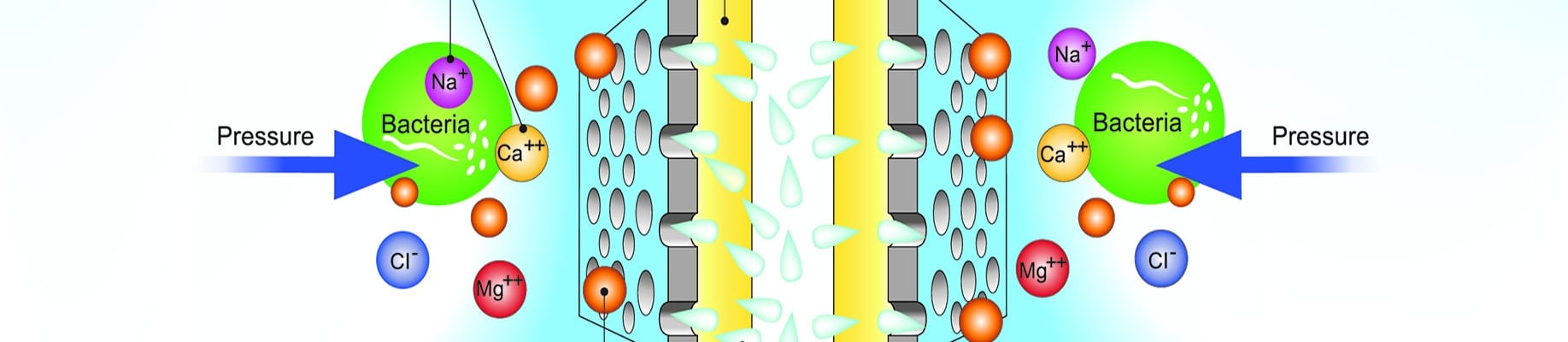

Compared to conventional clarifier techniques, tubular ultrafiltration is a more effective method of ensuring the treated wastewater stream is free of all precipitated metal hydroxide/sulfides/carbonates. The resulting high-quality permeate can be reclaimed in its existing state, fed directly to reverse osmosis equipment for reuse, or discharged to sewer.

It is important to note that while tubular ultrafiltration can process solids concentrations of up to 18 percent (w/w), the most efficient operation normally occurs between 3 percent and 5 percent solids. To produce dewatered solids, for landfill disposal, the sludge is normally drawn off and passed through a conventional thickening/filter press process or similar processes. Recycling supernatants from the sludge-handling processes through tubular membrane filtration helps ensure that the only outputs are the filtered water and the compact solids cake.

The Precipitation Method

Another common method is hydroxide precipitation due to its comparative simplicity. Sulfide precipitation has some advantages, but to minimize the risk of producing toxic levels of hydrogen sulfide gas, pH and oxidation-reduction potential (ORP) must be carefully controlled.

Benefits of Precipitating Chelated Metals with Membrane Technologies

Read the full article at watertechonline.com

For more information on removing heavy metal ions from your industrial wastewater contact PRAB, or request a quote today.