The ability to recover valuable cutting fluid from metalworking scrap provides manufacturers the ability to reduce new fluid purchases and other related expenses like haul-away and disposal costs. Because the scrap is separated from the fluid the metalworking operation can also improve the value of its scrap going to the recycler.

Companies weighing the options when purchasing new capital equipment like metal scrap processing and fluid recycling systems have the significant advantage of making a more informed decision of an application’s success and the expected return on investment before the purchase is made by having the equipment supplier perform material testing. This testing can answer many questions such as:

In material testing, a throughout assessment of the processes and application take place where material details, pounds per hour, and more are outlined along with the manufacturer’s goals and requirements. Once all the details are laid out the specific equipment solution is recommended to achieve the operational goals. Then, to demonstrate the scrap processing system’s capabilities and potential ROI to the customer, application-specific testing and reporting of the proposed system is conducted.

Groundwork Example from an Automotive Powertrain Manufacturer

Like most companies weighing the benefits of new or replacement metal chip and fluid processing equipment, one US based automotive powertrain manufacturer wanted to quantify the return on potential new metal scrap processing system, prior to purchase and installation of the new equipment.

The company had a demanding production process. So, the ability to recover the maximum amount of stamping oil from its steel stamping scrap would provide them the ability to reduce future stamping oil expenses, reduce haul-away and disposal costs, and improve the value of its stamping scrap.

As part of its value-added service, PRAB simulated the manufacturer’s process for separating the oil from the metal scrap at PRAB’s facility test lab using the metal scrap processing equipment that would be installed at the manufacturer’s plant. During the test, an engineer dumped two 55-gallon barrels of small stamping scrap material provided by the powertrain manufacturer into a conveyor infeed hopper. The material moved up the system’s conveyor and discharged into a diagonal shaft wringer. The wringer dried the chips and shells and discharged them back into the customer-supplied barrel.

Test Results & Conclusion

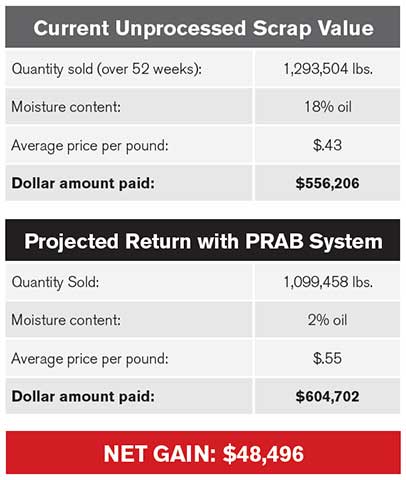

As a result of this testing, approximately 10 gallons of fluid was recovered lowering the moisture content of the scrap from 18% down to 2%. The full test results including amount of recovered oil, scrap volume reduction, throughput rate, and other test data was provided to the customer.

After reviewing the testing documentation and receiving the estimated return, it was evident that the wringer/conveyor system tested was the best choice for the powertrain manufacturer’s operation. Installed in February 2019, the new metal scrap processing system enables the company to successfully separate scrap from fluid, lowering its moisture content and allowing for the recovery of up to 98% of stamping oil for recycling or reuse.

After testing, a major metal recycling company provided an estimate of the projected return on investment for the powertrain supplier’s dry metal scrap. The estimate showed an approximate net gain of $48,496 from lowering the moisture content.

For more information regarding PRAB, please visit prab.com or contact us.

In this paper, we examine some of the factors that can significantly impact profit margins for metalworking shops. Additionally, we will make the case for minimizing that impact with metal scrap processing equipment and fluid recycling systems. Read our white paper