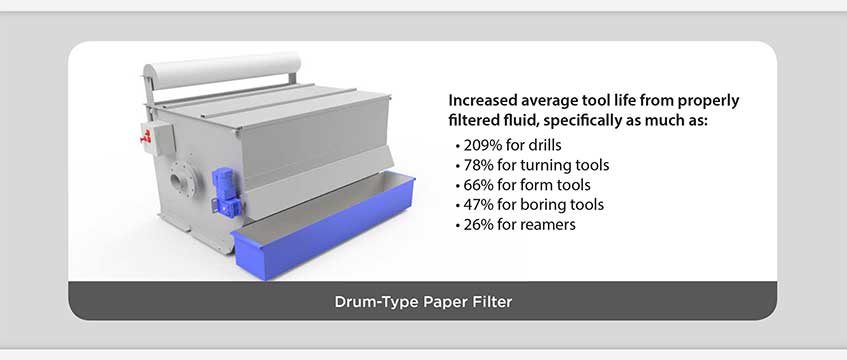

PRAB Drum-Type Paper Filters

Proven to Improve Surface Finish by an Average of 27%Small-Footprint Solution for Solids Filtration

PRAB Drum-Type Filters occupy one-third of the floor space of a traditional paper bed filter, saving valuable work space in your facility. Filtered fluid can be reused, lowering your operational costs.

Top Features & Benefits:

- Can be used for both ferrous and non-ferrous metals

- Disposable paper filter media is available in a variety of grades to meet your specific requirements

- Filter media surface is automatically indexed only when needed

- Automatic self-cleaning and self-monitoring system

- Longer coolant life

- Removal of particulate down to 25 micron level

- Prolongs tool life

- Improves surface finish of the component part

- Units are available with flow rates up to 525 GPM

Backed by the PRAB Difference

Significantly Lower Your Operational Costs

Operation:

The coolant is pumped from the machining center or grinder to the center of the drum via a distribution trough. The drum is lined with a non-woven filter media. The liquid then flows through the media, removing particles in suspension, and discharges through the bottom of the unit into a sump or tank. As the media blinds off and the coolant level rises to a predetermined level in the drum, a sensor activates the media advance mechanism, rotating the drum and exposing new media.

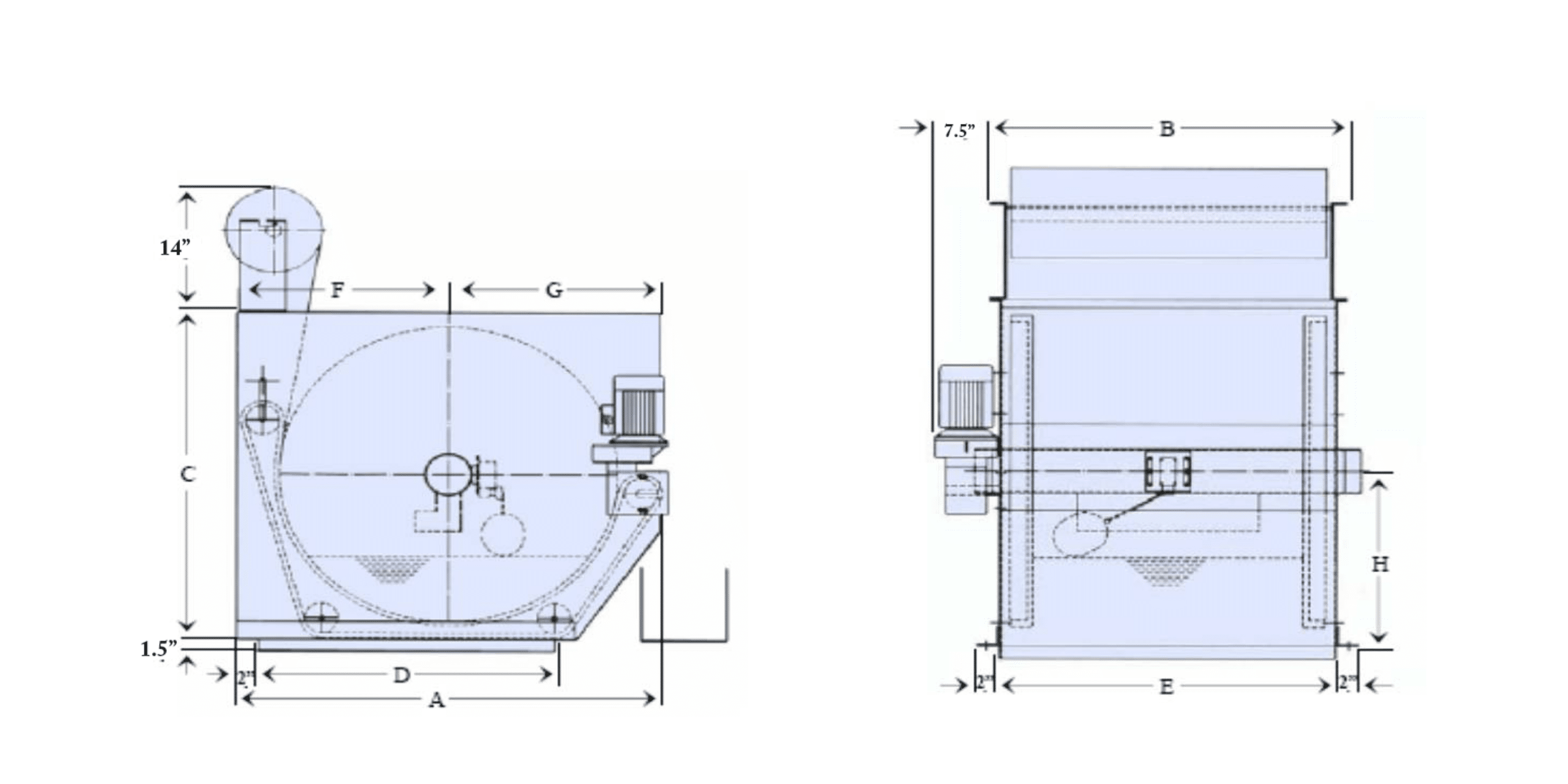

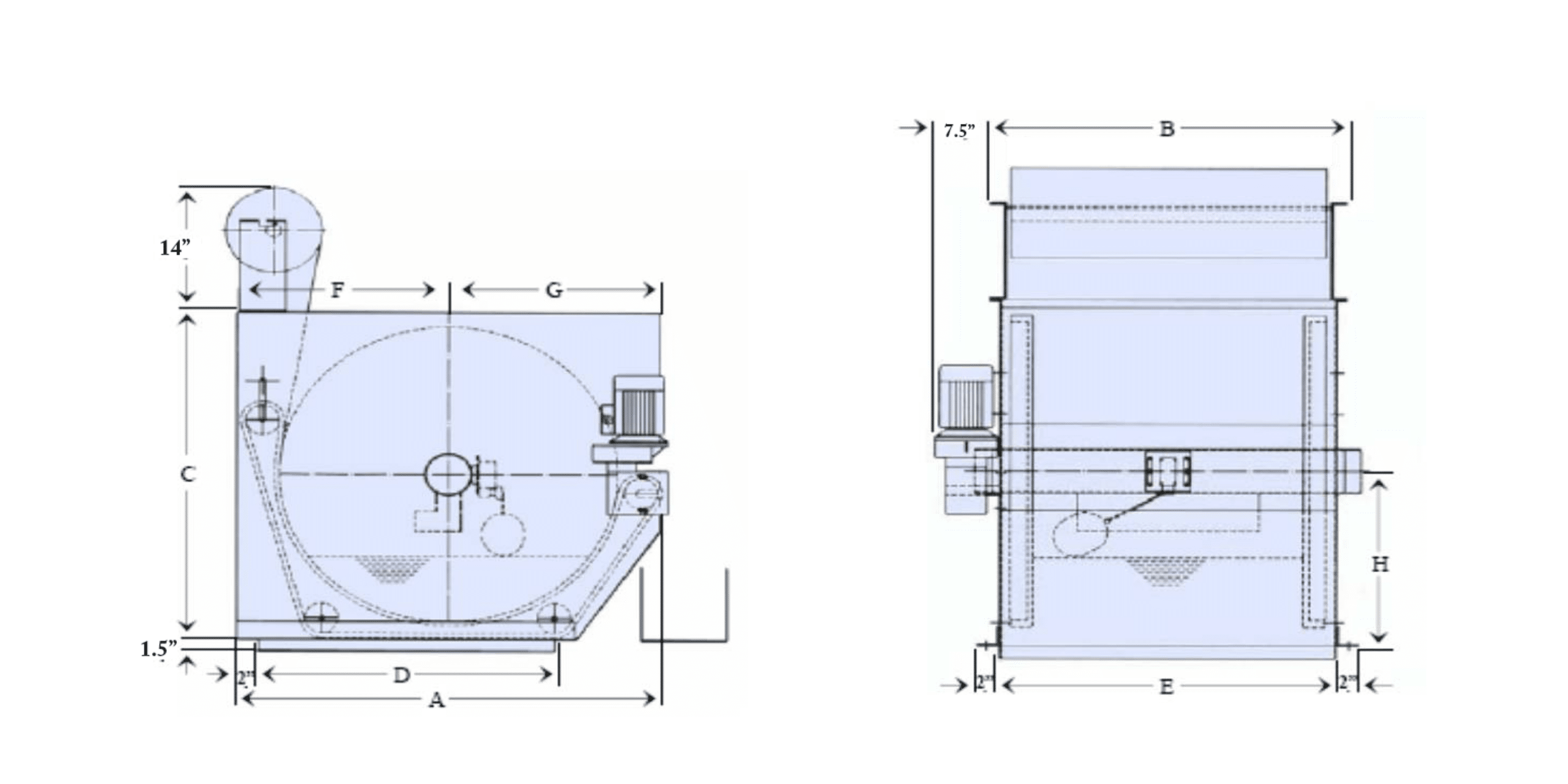

Model

Flow Rate*

(Water)

Drum

Diameter

Paper

Width

A

B

C

D

E

F

G

H

Motor

HP

Inlet

DF-140

35 GPM

22″

19.5″

30″

23″

25″

23″

21″

15″

15″

13″

1/3

3″

DF-200

50 GPM

22″

28″

30″

31″

25″

23″

30″

15″

15″

13″

1/3

3″

DF-360

95 GPM

31.5″

28″

40″

31″

35″

28″

29″

20″

20″

18″

1/3

4″

DF-500

130 GPM

31.5″

39″

40″

43″

35″

28″

41″

20″

20″

18″

1/3

4″

DF-1000

260 GPM

39″

39″

42″

43″

43″

35″

41″

23″

23″

22″

1/3

8″

DF-1500

390 GPM

39″

59″

42″

62″

43″

35″

61″

23″

23″

22″

1/3

8″

DF-1510

340 GPM

59″

39″

68″

43″

63″

55″

41″

34″

34″

34″

1.5

8″

DF-1515

525 GPM

59″

59″

68″

62″

63″

55″

61″

34″

34″

34″

1.5

8″

DF-1520

710 GPM

59″

78″

68″

82″

63″

55″

80″

34″

34″

34″

1.5

8″

*Flow rates above are based on water soluble coolant and 50 micron clarity. All dimensions are for reference only.

*Contact PRAB for flowrate with oil applications.

Clean coolant discharge dimensions: “D” by “E”

Applications:

- All grinding applications

- General machining

- Honing and gear cutting

- Lathe operations

- Parts washers

- Phosphatizing baths

- Tube and rolling mills

- Waste treatment

- Wire drawing