The PRAB Vertical Axis Crusher (VAC II) provides continuous, positive feed operation for high volume scrap reduction on the plant floor. Nested wads of metal turnings take up valuable floor space, are a safety hazard and have reduced scrap metal recycling value due to added processing costs. The vertical axis crusher is one of the most effective pieces of scrap metal processing equipment for quickly and safely creating flowable, thumbnail-sized chips from wads of turnings.

System Benefits:

“The reason we purchased PRAB’s equipment is because it can keep up with production, it is fully automatic, clean, and very user friendly. I used to work in a shop that had PRAB equipment and it ran 24/7, with very little maintenance. When it came time to look at scrap handling systems, I wanted to go with what I felt was the best.”– Gary Sroufe, C&A Tool’s multi-spindle “go-to guy”

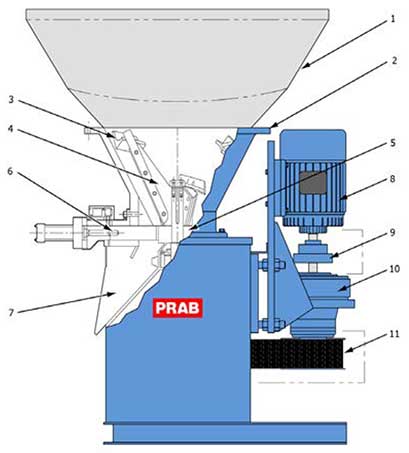

VAC II Components

Optional auto lube systems are available for automatic greasing of bearings-improving bearing performance and eliminating maintenance required for manual greasing.

VAC II Operation

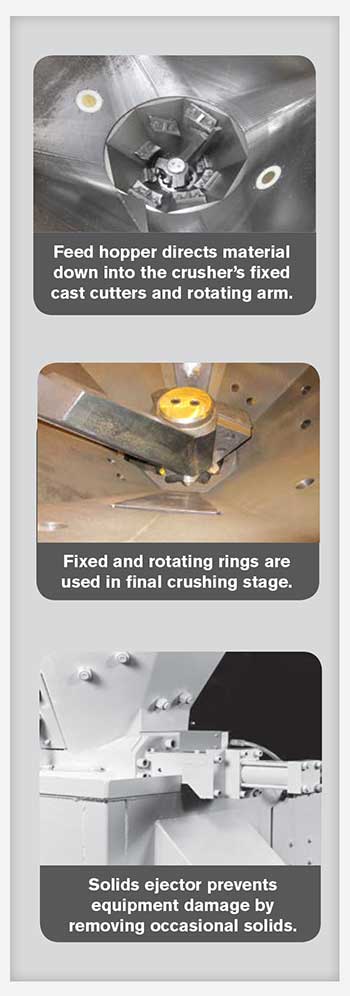

Metal turnings are fed into the VAC’s feed hopper (#1 above) which directs the material down into the crusher’s cast alloy hopper (#2 above). Fixed cast cutters (#3 above) and the rotating feeder arm (#4 above) reduce the turnings to small pieces. Final crushing is done as the material passes between the fixed cutter ring and the rotating cutter ring (#5 above).

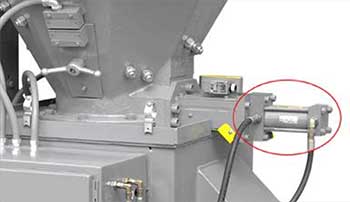

VAC II Automatic Solids Ejection Feature

Under normal operation the solids ejector is closed. When an occasional solid is encountered, the ejector snaps open allowing the solid to be discharged. The ejector automatically closes for continued operation.

*Capacity varies with different types of material, scrap characteristics, and incoming bulk density. For precise output figures ask for a FREE material test!

*Feed hoppers are required to facilitate loading. Available in multiple sizes to fit your application requirements.