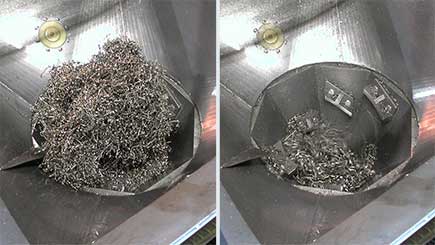

Reduce metal turnings and bulky wads into shovel-grade chips with a vertical axis crusher.

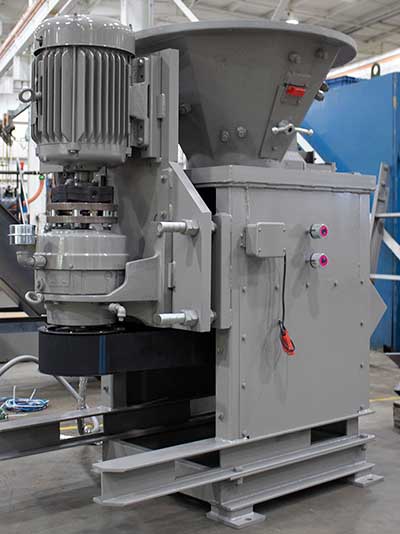

The PRAB vertical axis metal crusher provides continuous, positive feed operation for high volume scrap reduction on the plant floor. Nested wads of metal turnings take up valuable floor space, are a safety hazard and have reduced scrap metal recycling value due to added processing costs. The PRAB vertical axis crusher is one of the most effective pieces of scrap metal processing equipment for quickly and safely creating flowable, thumbnail-sized chips from wads of turnings.

Turnings are fed into the crusher’s feed hopper either by self-dumping hoppers, a plant-wide conveyor system, or an automated dump system with standard barrels or chip carts. The crusher’s feed hopper housing -with fixed cast cutters and rotating cutter- then directs the material down into the fixed and rotating cutter rings, where the material is reduced to flowable thumbnail sized chips.

The exclusive, PRAB-designed solids ejector automatically discharges bar-ends. This critical component protects the scrap metal equipment from damage, virtually eliminates downtime from lodged parts, and maximizes labor allocations.

These crushers can be used as stand-alone units or as part of a larger chip processing or scrap removal system. Other volume reduction scrap metal equipment designed and manufactured by PRAB includes the Horizontal Axis Crusher and Shredder.

Advantages of the PRAB Vertical Axis Crusher include:

PRAB Vertical Axis Metal Crushers can be used as stand-alone units or as part of a larger chip processing and scrap metal recycling system. Other volume reduction scrap metal equipment designed and manufactured by PRAB includes the Horizontal Axis Crusher and Shredder.

Features

Options

PRAB Vertical crushers can be used as stand-alone units or as part of a larger chip processing, or scrap removal system. Other volume reduction scrap metal equipment designed and manufactured by PRAB includes the Horizontal Axis Crusher and Shredder.

|

Nominal Capacity* (steel) |

Footprint |

Motor Power |

Net Weight |

|

1-2 tons/hr |

54 in x 40 in |

20HP |

3,000 lbs |

*Capacity varies depending on specific type of material. For accurate output figures please contact us to

ask for a FREE test drive.

*Feed hoppers are required to facilitate loading (available in multiple sizes).

How PRAB Vertical Axis Crushers Work

Watch as PRAB design Engineer, Jack Huver, explains the design elements of this powerful scrap metal turnings crusher. See the PRAB Vertical Axis Crusher operate as it reduces a full 55 gallon drum of Aluminum metal turnings into flowable chips in seconds.

PRAB Steel Turnings – Vertical Axis Crusher

PRAB’s vertical axis crusher reduces bushy wad of turnings to flowable chips and reduce downtime by automatic dumping into the vertical axis metal crushers

Product Brochures

Product Brochure: Vertical Axis Crusher

Case Studies

Case Study: C&A Tool Increases Profitability, Maintains Clean Facility With Chip Processing System

Case Study: Machining Company Achieves Considerable Cost, Space and Labor Savings with a PRAB Crusher/Wringer System

White Paper

White Paper: 8 Problem Areas Affecting Metalworking Operation Profitability

White Paper: Avoiding Accidents, Injuries & Illnesses In Metalworking Operations

White Paper: Green Engineering

White Paper: Reducing Haul-Away Costs in Metalworking Operations

White Paper: Prioritizing Plant Housekeeping In A Metalworking Operation

Other Downloadable Content

PRAB Chip Processing Systems All Product Brochure

PRAB Builds Equipment for the Toughest Jobs in Manufacturing and Metalworking

Download Address the Most Common Issues to Maximize Growth By Teresa Phillips, Senior Marketing Specialist, PRAB Introduction There are numerous areas in metalworking operations that can affect operational profitability, but eight top problem areas are common to many manufacturers. This whitepaper touches on each of the 8 problem areas, explains how they impact profitability, and what can […]

Metalworking operations aren’t struggling to find work these days, thanks to a strong economy and a healthy construction market. Unfortunately, the dwindling number of highly skilled workers with deep industry knowledge poses a more serious problem that must be dealt with to ensure that productivity keeps pace with demand. According to industrial supply company Grainger, 59% of metalworking firms […]

Download Proven To Reduce Metal Scrap Volume By As Much As 90% Documented Results Achieved by PRAB Customers: INCREASED REVENUE“We get $0.17 per pound more for our briquetted material over loose chips.”– Jack Rovan, Martin-Baker Plant Manufacturing Manager IMPROVED EFFICIENCY & SAFETY“PRAB has truly helped us get more money for our waste metal and improve our […]