Quiet, efficient transfer of all types of machining scrap with the in-floor scrap conveyor.

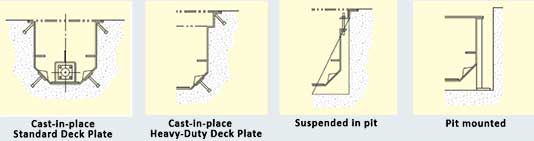

Convey all types of metal chips, fines and turnings, wet or dry bushy wads, and tramp metal solids, in a liquid-tight trough. Ideal for high-volume coolant-flow applications.

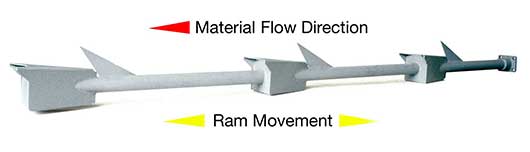

In-floor trough conveyors are available as a free-floating ram design or guided ram scrap removal system.

Harpoon® Conveyor

Push-Bar™ Conveyor

PRAB Harpoon Conveyor

Harpoon Conveyor running moving metal turning through coolant.

Product Brochures

Product Brochures: In-Floor Trough Conveyors

White Paper

White Paper: Avoiding Accidents, Injuries & Illnesses In Metalworking Operations

Other Downloadable Content

Conveyor Solutions

Die Cast Scrap Conveyor Systems

PRAB Builds Equipment for the Toughest Jobs in Manufacturing and Metalworking

“We get $0.17 per pound more for our briquetted material over loose chips.”– Jack Rovan, Martin-Baker Plant Manufacturing ManagerProven Results Achieved for PRAB Customers: Documented reduction of scrap volume by as much as 90% Increased scrap value up to 25% Reclaimed up to 99% of cutting fluids “We have seen around […]

There isn’t an employer in existence that shouldn’t consider slips and falls to be a significant safety concern in its facilities. In an article about overlooked hazards and risk zones in the workplace, Facility Executive magazine cites some sobering numbers: Same-level slip and fall accidents are the leading cause of workplace injuries and totaled almost 200,000 in 2015, according to […]

Proven to Raise Productivity Up To 60% Documented Results Achieved by PRAB Customers Long Lasting Equipment: Conveyors Still Operating in the Field After 57 Years Scrap aluminum from die cast trim presses drop onto oscillating conveyors that feed onto dual under-floor centralized collection oscillators. Oscillating conveyor deposits scrap into a large 6” […]