Magnetic chip conveyors transfer wet or dry ferrous scrap without carryover.

PRAB’s magnetic chip conveyors effectively transfer wet or dry ferrous chips, stamping slugs, turnings, parts or die scrap without carryover.

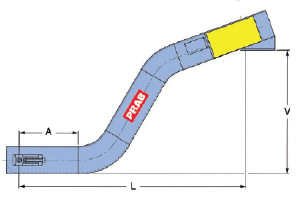

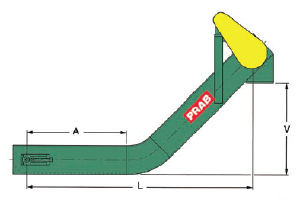

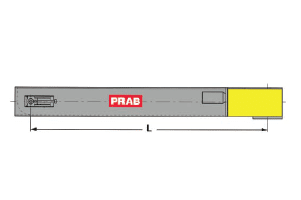

This scrap conveyor system moves material with the aid of permanent ceramic magnets located under a stainless-steel slider bed. An oil reservoir in the base of the conveyor self-lubricates the chain for quiet performance and low maintenance of this scrap handling system.

The PRAB Magnetic Conveyor is available with stainless steel slider bed in smooth or Rigidized® surfaces. This system can be built in a heavy-duty model or as a standard scrap handling system as described below.

PRAB Ferrous Material – Magnetic Conveyor

PRAB’s Magnetic Conveyor transports ferrous material downstream.

PRAB Cast Iron Fittings Magnetic Conveyor

PRAB’s magnetic conveyor transports chromate coated cast iron conduit fittings.

Product Brochures

Product Brochures: Magnetic Conveyors

Other Downloadable Content

Conveyor Solutions

PRAB Builds Equipment for the Toughest Jobs in Manufacturing and Metalworking

“We get $0.17 per pound more for our briquetted material over loose chips.”– Jack Rovan, Martin-Baker Plant Manufacturing ManagerProven Results Achieved for PRAB Customers: Documented reduction of scrap volume by as much as 90% Increased scrap value up to 25% Reclaimed up to 99% of cutting fluids “We have seen around […]

Proven To Raise Productivity Up To 60% Documented Results Achieved by PRAB Customers Decreased Downtime Downtime Before PRAB: 3-4 hoursDowntime After PRAB: 2 minutes Safer Workplace “Our process of disposing metal scrap has become more ergonomic and safer.” – Jack Rovan, Martin-Baker Long Lasting Equipment: Conveyors Still Operating in the Field After 57 Years PRAB Conveyors […]

Carryover (also known as carryback) is an issue that can cause maintenance issues for even the most efficient stamping operation. In addition to the potential production and revenue lost, these delays can also lead to injuries when workers attempt to clear any blockages. Regardless of if the material being conveyed consists of slugs, trim pieces, or stringy turnings, PRAB […]