Chain conveyors made to handle severe-duty, highly abrasive, metal chips, fines and swarf.

Transfer and elevate the most difficult and abrasive wet or dry metal chips, fines, swarf, die scrap and other materials with this rugged, chain driven, liquid-tight conveyor.

Every part of this rugged chain driven conveyor is designed for severe duty. The Heavy-duty, abrasion-resistant flight bars of the scrap conveyor feature an exclusive bolt-free connection so they stay strong under grueling conditions. The abrasion-resistant steel press-formed trough is liquid tight and comes standard with safety covers.

Advantages of the PRAB Drag Chain Conveyors include:

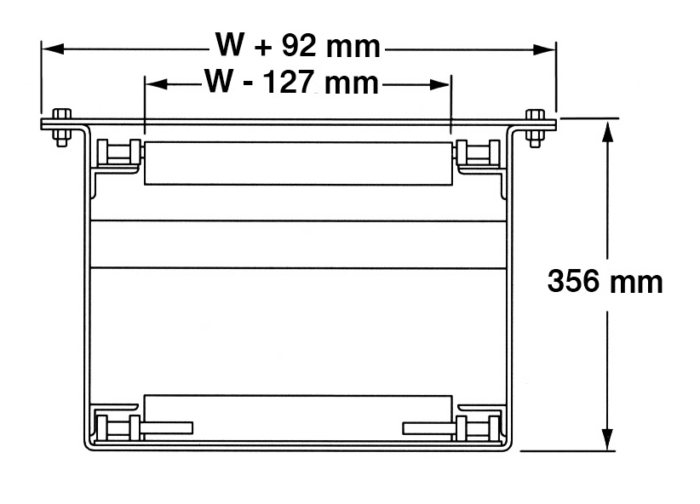

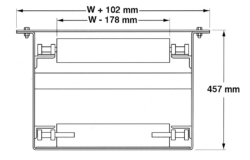

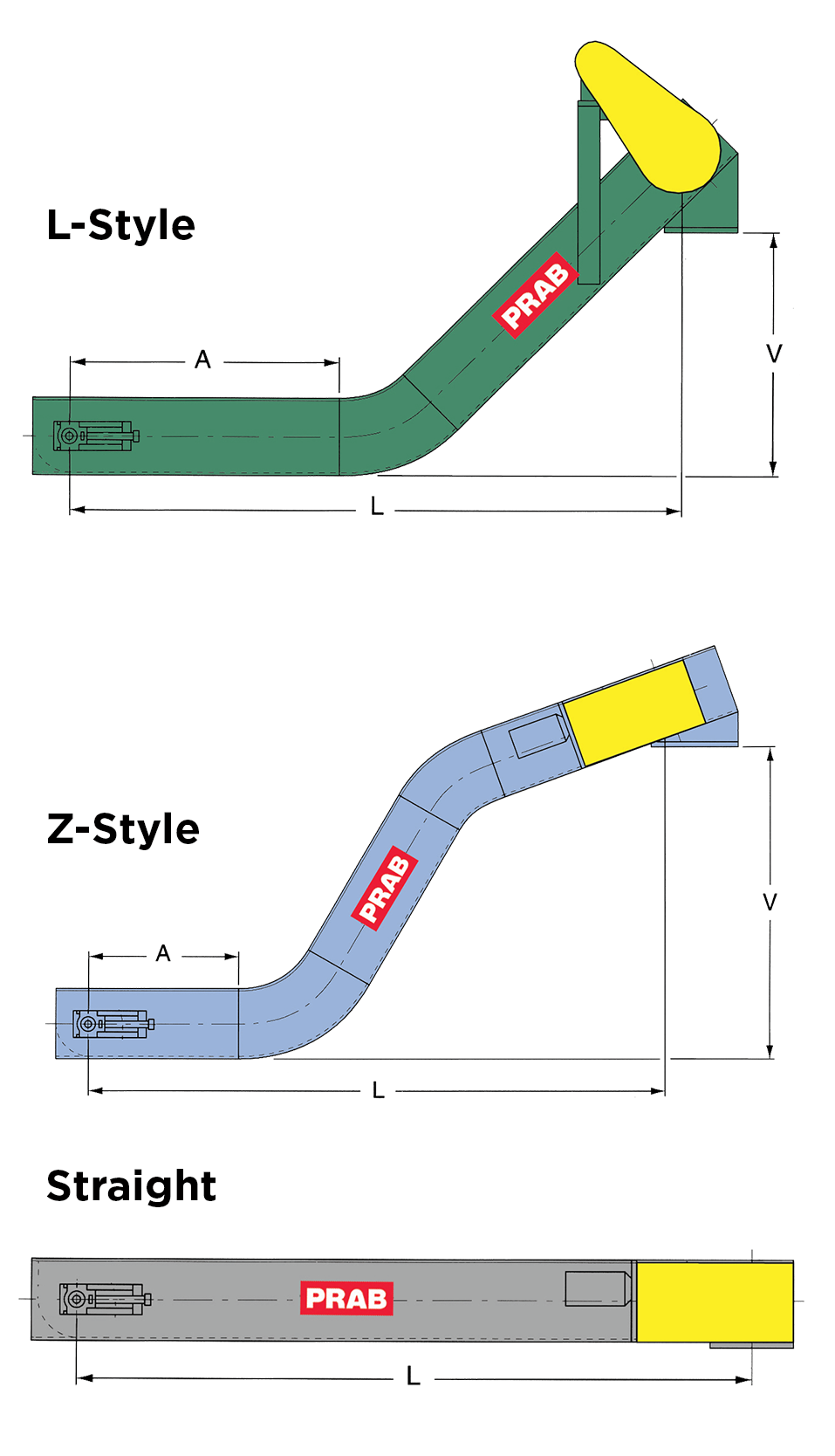

PRAB offers two models- Series #348 and Series #458, in three configuration styles designed to convey materials for scrap recycling ranging in weight and bulk density. This scrap material conveyor is also available with in-feed hoppers and metering plates, and can also be customized with coolant pumps for integration with a chip and fluid filtration system.

Z-Style

L-Style

Straight

Product Brochures

Product Brochure: Drag Conveyor

White Paper

White Paper: Avoiding Accidents, Injuries & Illnesses In Metalworking Operations

Other Downloadable Content

Conveyor Solutions

PRAB Builds Equipment for the Toughest Jobs in Manufacturing and Metalworking

Automating the handling of metal scrap and spent fluids is crucial to protecting your workforce.By Mike Hook, Sales & Marketing Director, PRAB Introduction In a report issued during the 2018 National Safety Council Congress & Expo, the Campbell Institute-a respected global thought leader on placing environment, health, and safety at the core of […]

Proven to Raise Productivity Up To 60%Documented Results Achieved by PRAB Customers Enhanced Productivity Downtime Before PRAB: 3-4 hours Downtime After PRAB: 2 minutes Safer Workplace “Our process of disposing metal scrap has become more ergonomic and safer.” – Jack Rovan, Martin-Baker Long Lasting Equipment: Conveyors Still Operating in the Field […]

Download Automated Systems and Domestic Sourcing Will Contribute to Sustainable U.S. ProductionBy Mike Hook, Sales & Marketing Director, PRAB Introduction Global health events. Trade wars and tariffs. Political discord. Rising foreign labor costs. External factors such as these have had a major impact on U.S. manufacturing. Many companies were challenged in 2020 just to complete ordinary day-to-day production […]