Collaborative Design

Automated Scrap Handling

Centralized Scrap Management System

Traversing Conveyors

A stamping operation at a custom parts manufacturing plant near Detroit, Michigan, USA needed to improve their scrap handling process. The stamping operation had a 1,000 ton press and required die changes 7 to 9 times per shift. The plant ran 3 shifts over a 6 day period. There was no underground pit; therefore all of the scrap came off the press onto conveyors that were manually placed into position at ground level. This labor-intensive, manual process took 20 to 30 minutes per die change and cut into production time, was not safe for workers, and added unnecessary costs to the operating budget.

A stamping operation at a custom parts manufacturing plant near Detroit, Michigan, USA needed to improve their scrap handling process. The stamping operation had a 1,000 ton press and required die changes 7 to 9 times per shift. The plant ran 3 shifts over a 6 day period. There was no underground pit; therefore all of the scrap came off the press onto conveyors that were manually placed into position at ground level. The power source for the conveyors would lie on the production floor in the path of workers and other plant staff. In addition, the scrap would fall off of the conveyors during the stamping operation, relying on workers to manually pick up sharp metal pieces. For a die to be changed, the series of conveyors needed to be disconnected from power, manually moved to a temporary staging location, then the bolster had to be hoisted into place, and finally the series of conveyors moved back into place and re-connected to the power source. This labor-intensive, manual process took 20 to 30 minutes per die change and cut into production time, was not safe for workers, and added unnecessary costs to the operating budget.

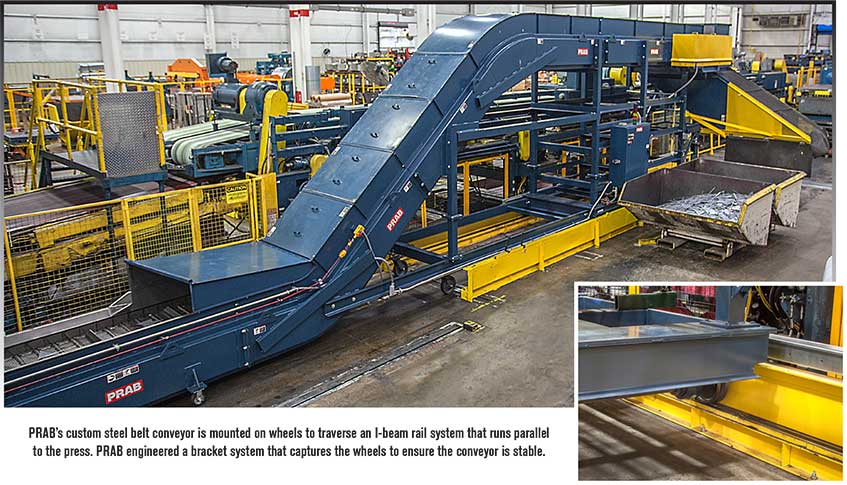

PRAB’s Z-style steel belt mobile conveyor will traverse from the front of the press to enable a new bolster and die to be rolled into the press.

PRAB’s Z-style steel belt mobile conveyor will traverse from the front of the press to enable a new bolster and die to be rolled into the press.

The goal of the stamping facility was to have a permanent conveying system that would allow for the die to be changed easily, increase the efficiency and accuracy of scrap collection, and provide a safe work environment for all employees.

A custom engineered a 6” Pitch Traversing Steel Belt Conveyor that spanned 50’ and lifted the stamping scrap 13’ safely to a bin.

The conveyor is operated with a hand control that moves the conveyor across a rail system which is securely anchored to the floor. The conveyor moves 23 feet at a rate of 15 fpm and handles 20,000 lb/hr of metal stamping scrap. At the conveyor movement- cycle completion, the start of the conveyor is completely out of the way of the press. This allows the old die to be removed from the press and the new die put into place. When the conveyor is in operation, all of the scrap is collected on the steel belt conveyor and carried up over head in an enclosed frame. The scrap is safely discharged from a shielded shoot into a scrap bin. The bin is hauled away when full to an outside container using fork lifts.

The Traversing Steel Belt Conveyor from PRAB cut the die change process by 50% and operating costs by an average of 12 to 18% per job. Plant safety was also improved because electrical connections were removed from all walk-ways, and scrap did not have to be manually handled. The reduction in labor for die-change allowed operators to train in other areas of the plant operations.